I have been free-hand sharpening my bandsaw blades just by touching the top of each tooth

with a Dremel tool at a slight angle (see here).

I have been free-hand sharpening my bandsaw blades just by touching the top of each tooth

with a Dremel tool at a slight angle (see here).

I have been free-hand sharpening my bandsaw blades just by touching the top of each tooth

with a Dremel tool at a slight angle (see here).

I have been free-hand sharpening my bandsaw blades just by touching the top of each tooth

with a Dremel tool at a slight angle (see here).

But sharpening 1/4" wide blades with 6 teeth per inch (1 tooth every 4 mm), it gets a bit dizzying focusing so close on so many teeth for so long. And it happened that the 1/4" 6 tooth-per-inch (TPI) blades on my 20" bandsaw (132" long) and my 16" bandsaw (105" long) both got dull at the same time. That's 1422 teeth to sharpen.

So I built this jig to help with the process.

So I built this jig to help with the process.

The blade fits in a slot, and the lever at left advances the blade by one tooth every time I lift it and drop it back down. I even added a screw under the pusher that lifts it up to prevent it from engaging any teeth beyond the next one, so I can't accidentally advance it by two teeth.

Then I needed something to hold the Dremel tool to touch each tooth, roughly

like this.

Then I needed something to hold the Dremel tool to touch each tooth, roughly

like this.

I normally used one of those easily breakable cut-off disks on the Dremel, but I realized I had this stone and I figured I'd be less likely to break the stone with experiments while building a sharpening jig.

I used an old hinge (in the back) to act as a pivot, with the Dremel tool

mounted to a piece of sheet metal that fits behind the plastic nut

on the front of the Dremel tool. The hole needed to be 16 mm in diameter.

I used a step drill to drill that hole, which worked really well in the

sheet metal (I didn't have any other metal drills that size).

I used an old hinge (in the back) to act as a pivot, with the Dremel tool

mounted to a piece of sheet metal that fits behind the plastic nut

on the front of the Dremel tool. The hole needed to be 16 mm in diameter.

I used a step drill to drill that hole, which worked really well in the

sheet metal (I didn't have any other metal drills that size).

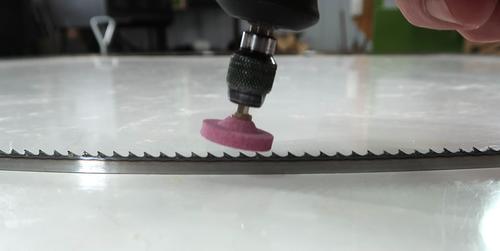

But with this arrangement, the Dremel tool would come to rest on the blade,

and it would be better if I had to push it down. So I added a spring

to the base, and a screw in the part that swings down to adjust how far

the spring keeps it pushed up. (See red arrows.)

But with this arrangement, the Dremel tool would come to rest on the blade,

and it would be better if I had to push it down. So I added a spring

to the base, and a screw in the part that swings down to adjust how far

the spring keeps it pushed up. (See red arrows.)

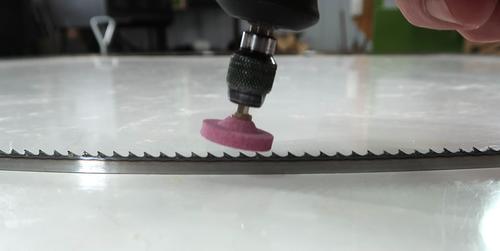

A close-up of he Dremel tool grind stone above the blade, supported by the spring.

A close-up of he Dremel tool grind stone above the blade, supported by the spring.

Trying it out, I found the blade would skip out of the slot from time to time,

so I added a ball bearing to push it down. The ball bearing is an old roller skate

ball bearing, and mounted on a piece of coat hanger wire, screwed down on the

right side. This gives it springiness to hold it down.

Trying it out, I found the blade would skip out of the slot from time to time,

so I added a ball bearing to push it down. The ball bearing is an old roller skate

ball bearing, and mounted on a piece of coat hanger wire, screwed down on the

right side. This gives it springiness to hold it down.

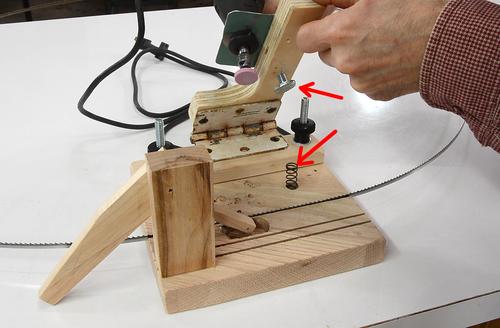

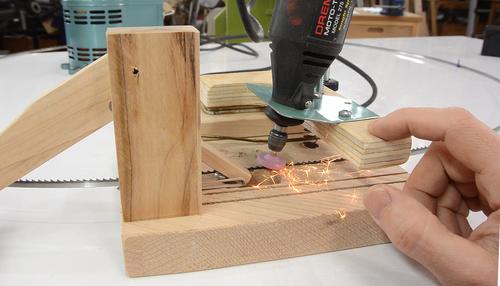

Trying it out. I have the Dremel tool plugged into a variac (in the background)

to slow it down a bit because this one is not variable speed.

Trying it out. I have the Dremel tool plugged into a variac (in the background)

to slow it down a bit because this one is not variable speed.

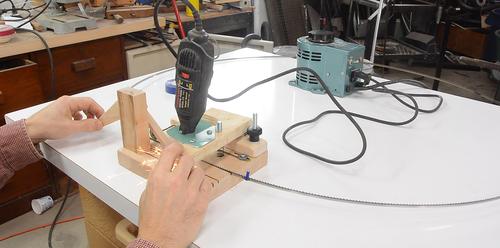

The action from the operators view point. I'm always alternating lifting and lowering

the lever, then briefly tapping on the Dremel tool mount to touch the teeth.

I can sharpen nearly two teeth per second once I get into a rhythm.

The action from the operators view point. I'm always alternating lifting and lowering

the lever, then briefly tapping on the Dremel tool mount to touch the teeth.

I can sharpen nearly two teeth per second once I get into a rhythm.

But after sharpening the 132" long blade (792 teeth), when I tried it on the

saw, I could tell half of it cut much better than the rest.

My jig is much more consistent than my holding the Dremel tool by hand, so

I was always touching the teeth with exactly the same part of the

stone. That caused a groove to wear into the stone, which in turn affected the quality

of the sharpening. Working freehand there was always some variation with how

I touched the Dremel to the teeth, so I never got this sort of groove in the

cutting disk.

And working freehand was also slightly faster, though more stressful.

Freehand, I always end up nicking a few teeth from carelessness.

But after sharpening the 132" long blade (792 teeth), when I tried it on the

saw, I could tell half of it cut much better than the rest.

My jig is much more consistent than my holding the Dremel tool by hand, so

I was always touching the teeth with exactly the same part of the

stone. That caused a groove to wear into the stone, which in turn affected the quality

of the sharpening. Working freehand there was always some variation with how

I touched the Dremel to the teeth, so I never got this sort of groove in the

cutting disk.

And working freehand was also slightly faster, though more stressful.

Freehand, I always end up nicking a few teeth from carelessness.

I swapped the stone for a diamond disk and sharpened the blade again, at which point it was consistent again.

I can't call this experiment entirely a success. I know I will get the suggestion that I should fully automate the jig, but I don't think it would be worth the trouble. More automation means more things to go wrong, and more debugging and testing to get it to work. I usually only have one blade to sharpen at a time.

I also won't be adapting this to different sized blades. Right after this, I freehand sharpened a 93" long 2 TPI blade (13 mm between teeth) and that took so little time that it certainly wouldn't be worth setting up a jig for it.

Another suggestion I will probably get often is that I should make it so you don't have to take the blade out of the saw, but that is also a bad idea. With the blade on the wheels, there is just too much inertia from the wheels, which means I couldn't advance and stop the blade as quickly, so sharpening the teeth would take quite a bit longer.

But if I was doing it again, I would try to come up with something to make it easier to sharpen freehand, just because that is faster.

Stoning bandsaw blades

Stoning bandsaw bladesTo my Woodworking website