Wooden gear cutting jig

There's nothing that symbolizes machinery like gears. Seeing that I

like to make machines out of wood, it follows then that I should want some

of these machines to have gears on them. Wooden gears, of course.

I have cut numerous wooden gears on my table saw for various machines,

such as my

Marble machine 2.

One of the biggest problems with this is precisely measuring the angle

between the teeth, and rotating the gear by exactly that much between cuts

on the table saw. With the gear jigged up on a shaft to hold it

securely, it isn't possible to attach a protractor to measure accurately.

And even when using a protractor, there is always the problem that

the protractor has to be moved (seeing that it doesn't span 360 degrees),

and the possibility of getting some slightly odd teeth intervals as a result.

To help rotate the

gear by a precise amount for the purpose of cutting teeth, I decided to build

some kind of mechanism for rotating the jigged-up gear. The idea is to

have something to roughly take the role of a machinist's dividing plate, but

much smaller, lighter, and less precise.

To help rotate the

gear by a precise amount for the purpose of cutting teeth, I decided to build

some kind of mechanism for rotating the jigged-up gear. The idea is to

have something to roughly take the role of a machinist's dividing plate, but

much smaller, lighter, and less precise.

Rummaging through my junk, I was fortunate enough to find a remote servo

(for controlling valves and such), of roughly 1940's technology.

The box consisted of a small split phase motor,

5 stages of reduction gears to a big gear on a half inch shaft, a rheostat,

and some sort of mechanical balance contraption to function a bit like a

bridge circuit to compare the rheostat in the box to some master rheostat

somewhere else. When unbalanced, the balance would connect either phase

of the split phase motor to AC power, causing it to rotate in either direction.

YouTuber AvE made a

video about one of

these servos

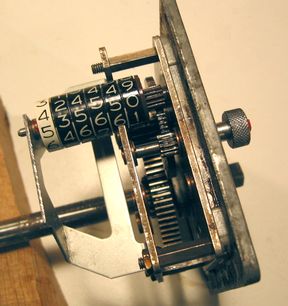

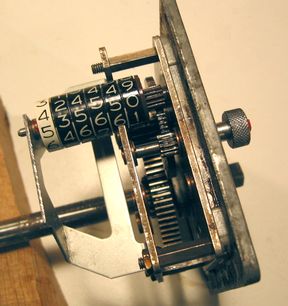

I removed the motor and the gears closest to it, leaving me with two

gears of reduction. I mounted the last remaining shaft and gear backwards

so that the long shaft protruded out through a hole I drilled in the aluminium

plate, and attached a knurled knob to it for fine adjustment.

I then needed some means of measuring rotations of the knob.

I originally thought of using a counter from a tape recorder, but I found

an old set of mechanical car odometer wheels in my parts collection. The gear attached

to the last wheel was exactly the right pitch to match with those in my

gearbox. Unfortunately, the first (0.1 km increments) wheel of the odometer

was designed to jam up on running backwards. The rest of the wheels

didn't have this property. So I moved the 0.1 km increment

wheel to the other end, and made the gear drive the 1 km increment wheel

directly. With the various gears, I got a 1:39.12 gear ratio.

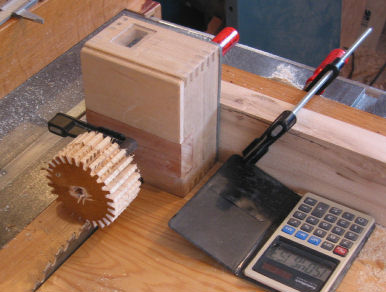

The gear cutting jig in action on the table saw.

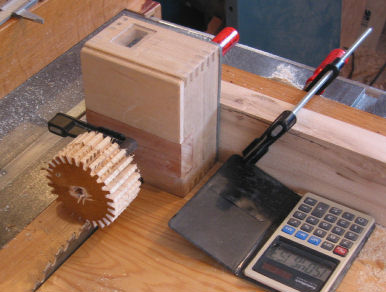

I then made a sturdy wooden box to attach to the aluminum frame of the gearbox,

and keep my gears free from dust. The way I use the jig on my table saw

sled causes the sawdust to get thrown directly towards the gearbox, so keeping

the dust out is important. I even made a little window for

the counter so no dust can get in that way either.

The whole mechanism runs really smoothly. A light twist to the output

shaft will set the odometer counter spinning. This turned out to be

a bit of a problem when cutting gears, because I always apply a slight amount

of torque to the output shaft while cutting to avoid random errors from

gear backlash. But with the mechanism turning so easily,

I need to add a brake to the input knob so that it doesn't start spinning

from this slight torque.

A gear ratio of 1:36 would have made the counter increments 1 degree.

Unfortunately, that was not the gear ratio that I had. I was already lucky

enough to have a gearbox as suitable for

the job as it was. Besides, most gears I make don't have a number of teeth

that would divide nicely into 360 anyway.

As it is, I have 391.2 counter increments per revolution. When

I cut the gears, I calculate how many increments I need to advance per tooth,

and then use the constant calculation feature of a calculator to generate

the numbers one at a time, and dial them on my counter. 391.2 increments

is unfortunately too few to just round to the nearest, so I have

to visually interpolate fractional increments to get decently accurate gear tooth spacing.

For most gears, I have to make two cuts per tooth, so I have to dial in two

angles per tooth.

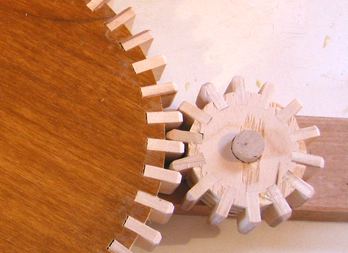

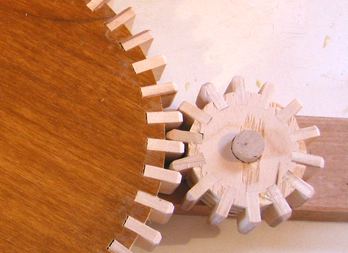

The two gears above were the first ones I cut with my jig. To round the tops

of the teeth, I used a square file, held at a 45 degree angle, and filed between

two adjoining teeth. This kind of approximates the ideal involute spur gear

tooth shape. These two gears mesh amazingly smoothly for being cut out of plywood.

Gears with inset teeth

Naturally, cutting the gears straight out of plywood

is not ideal because the wood grain is not aligned with the teeth.

Better gears can be made by inserting individual teeth

into a plywood wheel. Unfortunately, this means the teeth have to be

fairly narrow to leave enough plywood to hold them. At left are two gears made this way.

The small gear only has 14 teeth, and it

runs fairly noisily. This can be desirable for drawing attention,

as in "look, it has wooden gears!"

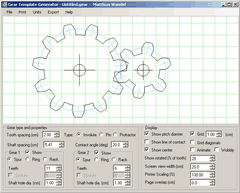

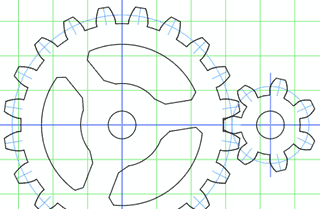

Since building the gear cutting jig, I have come up with a simpler solution for

getting all the gear angles. It's much easier to just make a protractor

template out of paper and stick it to the piece of wood.

This should help align the angles,

and with care should be more than accurate enough. You can make very

accurate protractor templates with an inkjet printer using my free

online gear template generator or

you could buy a copy of my fancy gear template generator.

To help rotate the

gear by a precise amount for the purpose of cutting teeth, I decided to build

some kind of mechanism for rotating the jigged-up gear. The idea is to

have something to roughly take the role of a machinist's dividing plate, but

much smaller, lighter, and less precise.

To help rotate the

gear by a precise amount for the purpose of cutting teeth, I decided to build

some kind of mechanism for rotating the jigged-up gear. The idea is to

have something to roughly take the role of a machinist's dividing plate, but

much smaller, lighter, and less precise.

How to make gears

How to make gears Cutting gears with a jigsaw

Cutting gears with a jigsaw Cutting gears with a table saw (freehand)

Cutting gears with a table saw (freehand) Free interactive gear template generator

Free interactive gear template generator

Gear design and gear

Gear design and gear