In the nearby town of Almonte, there is a clock on top of the old

post office. This clock runs, with its original mechanism. I got to

know James, who maintains and winds the clock, and he offered

to give me a tour.

In the nearby town of Almonte, there is a clock on top of the old

post office. This clock runs, with its original mechanism. I got to

know James, who maintains and winds the clock, and he offered

to give me a tour.

In the nearby town of Almonte, there is a clock on top of the old

post office. This clock runs, with its original mechanism. I got to

know James, who maintains and winds the clock, and he offered

to give me a tour.

In the nearby town of Almonte, there is a clock on top of the old

post office. This clock runs, with its original mechanism. I got to

know James, who maintains and winds the clock, and he offered

to give me a tour.

It's many flights of stairs up to the clock. On the second floor, I could see an enclosure for where the weight for the clock descends, though the weight was well above the second floor because the clock had been wound recently.

The weight shaft used to extend to the ground floor, but the restaurant that's there now didn't want the weight coming through the restaurant, so the shaft was shortened. The clock now no longer runs a whole week on a single winding.

Looking at the clock mechanism, there are many clever aspects of how it's designed, such as a simple weighted lever that needs to be engaged before the winding crank can be put on the shaft. This weighted lever provides a few minutes worth of power to the clock while the weight is wound up.

The mechanism that makes the bell ring once for one o'clock, twice for two,

and so on is simple and clever. Basically, a gear and a wheel with notches

that stop the ringing mechanism, 1 tooth apart for 1 o'clock,

2 for 2 o'clock, etc... After it has moved 12 notches for 12 o'clock,

it's back to 1. So the gear has 1+2+3...+12 teeth, or 78 in total.

The mechanism that makes the bell ring once for one o'clock, twice for two,

and so on is simple and clever. Basically, a gear and a wheel with notches

that stop the ringing mechanism, 1 tooth apart for 1 o'clock,

2 for 2 o'clock, etc... After it has moved 12 notches for 12 o'clock,

it's back to 1. So the gear has 1+2+3...+12 teeth, or 78 in total.

The clockwork drives a shaft that turns once an hour, which then couples with a bevel gear to a shaft that goes up to the room behind the clock faces. There is another bevel gear at the top which couples to four bevel gears going to the four clock faces.

The vertical shaft actually turns slightly less than once an hour because the

top bevel gear is slightly larger than the other ones. Why larger? Well,

if it was the same size as the four bevels going to the faces, these bevel

gears would engage each other and jam the gearing.

The vertical shaft actually turns slightly less than once an hour because the

top bevel gear is slightly larger than the other ones. Why larger? Well,

if it was the same size as the four bevels going to the faces, these bevel

gears would engage each other and jam the gearing.

Each clock face has its own 1:12 gear reduction to drive the hours hand. There are also two counterweights behind the clock face to compensate for the weight of the clock hands.

James tells me the hands of the clock are offset quite a bit from the face. I imagine this is so they don't jam if there is ice build up on the clock face.

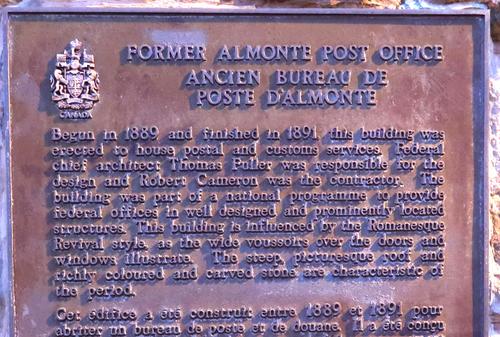

And the building itself is historic (though maybe not by European time scales).

And the building itself is historic (though maybe not by European time scales).

Imagine a time, when the clock tower at the center of town was the standard of reference that everyone set their clocks to!

Thanks James for giving me a tour of this clockwork.

James says he can give tours to others if they are interested in seeing the clock work. I should warn that it's many steps, and narrow and tight quarters to get up there. James' email address is:

Pager rotating machine

Pager rotating machine