Below-bowl ramps

The marbles that swirl around the bowl eventually fall out one of three

holes at the bottom. Two of these holes lead to ramps that move the

marbles over to where they are dropped onto percussion elements.

The third hole just drops them straight down.

The marbles that swirl around the bowl eventually fall out one of three

holes at the bottom. Two of these holes lead to ramps that move the

marbles over to where they are dropped onto percussion elements.

The third hole just drops them straight down.

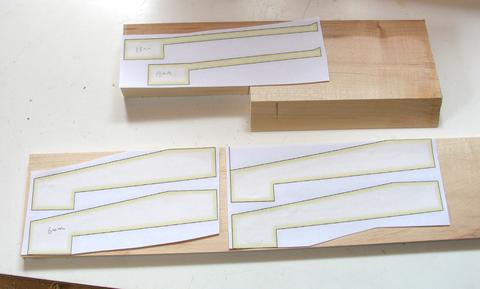

Each ramp is sandwiched together out of three layers, with the outside

layers 7 mm thick, and the middle layer 18 mm thick.

Here are my paper templates glued onto the pieces of wood I'm about to cut.

Each ramp is sandwiched together out of three layers, with the outside

layers 7 mm thick, and the middle layer 18 mm thick.

Here are my paper templates glued onto the pieces of wood I'm about to cut.

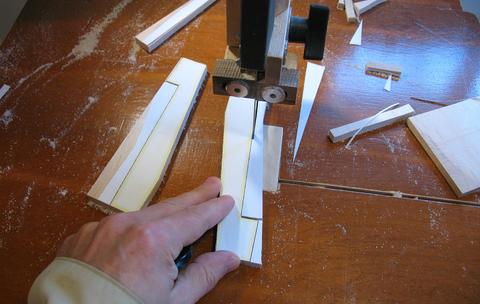

Cutting the pieces out on the bandsaw...

Cutting the pieces out on the bandsaw...

Clamped and waiting for the glue to dry. I pressed the part down on the table

in the orientation shown while applying the clamps to ensure proper alignment.

Be careful when you apply the clamps - they often cause parts to slip out of alignment.

Clamped and waiting for the glue to dry. I pressed the part down on the table

in the orientation shown while applying the clamps to ensure proper alignment.

Be careful when you apply the clamps - they often cause parts to slip out of alignment.

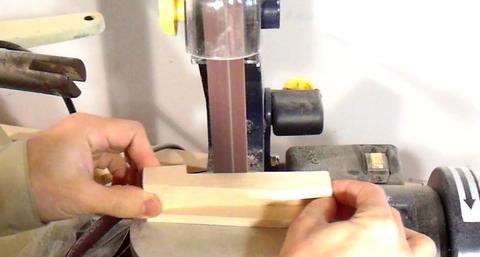

Cleaning up some of the rough edges after assembly.

Cleaning up some of the rough edges after assembly.

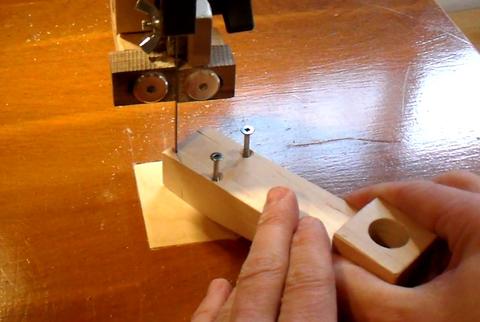

Once the glue was dry, I'm drilling the exit holes for the ramps.

I'm using a 5/8" (16 mm) drill. A drill that is a tiny bit larger would be ideal, but

such drill sizes are very hard to find. A 3/4" or 18 mm hole would be too large.

For a hole that large, marbles might go through a hole at an angle and then miss

their target below.

Once the glue was dry, I'm drilling the exit holes for the ramps.

I'm using a 5/8" (16 mm) drill. A drill that is a tiny bit larger would be ideal, but

such drill sizes are very hard to find. A 3/4" or 18 mm hole would be too large.

For a hole that large, marbles might go through a hole at an angle and then miss

their target below.

The problem with 5/8" or 16 mm is that some of the marbles are slightly larger than that and will get stuck in the holes.

My solution was to sand out the inside of the hole. I don't have a sanding spindle that small,

so I used a piece of 1/2" dowel (about 12 mm) and cut a slot in it. I then put a piece of

very coarse sandpaper in that slot. No need to glue the sandpaper into the slot, but the

important thing is that the lower edge of the sandpaer is at an angle. This helps the sandpaper

wrap itself around the dowel as the spinning dowel is pushed into the hole

My solution was to sand out the inside of the hole. I don't have a sanding spindle that small,

so I used a piece of 1/2" dowel (about 12 mm) and cut a slot in it. I then put a piece of

very coarse sandpaper in that slot. No need to glue the sandpaper into the slot, but the

important thing is that the lower edge of the sandpaer is at an angle. This helps the sandpaper

wrap itself around the dowel as the spinning dowel is pushed into the hole

With the drill lowered into the hole, the drill is moved up and down while the work piece

is pushed in various directions. Ideally, the hole will get enlarged by about half a

millimeter. Some larger marbles may still get stuck in the holes,

just put those marbles aside.

With the drill lowered into the hole, the drill is moved up and down while the work piece

is pushed in various directions. Ideally, the hole will get enlarged by about half a

millimeter. Some larger marbles may still get stuck in the holes,

just put those marbles aside.

Next drilling the mounting holes using a 9/64" (3.5 mm) drill.

A countersink is also added to the bottom of the ramp for the screw heads.

Next drilling the mounting holes using a 9/64" (3.5 mm) drill.

A countersink is also added to the bottom of the ramp for the screw heads.

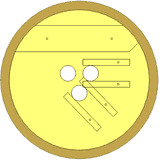

Marking the location for the pilot holes of the longer of the two ramps.

Make sure the ramp lines up with the hole in the bowl and that it points

towards the corner of the machine. The back edge

of the ramp should not extend past the edge of the hole, as space will be very tight.

Marking the location for the pilot holes of the longer of the two ramps.

Make sure the ramp lines up with the hole in the bowl and that it points

towards the corner of the machine. The back edge

of the ramp should not extend past the edge of the hole, as space will be very tight.

Also make a pencil line for the outline of the ramp on the bottom of the bowl.

Next hold the second ramp in place. Using the previously marked outline, mark how much

needs to be cut away from the end of this ramp to fit next to the other ramp.

Next hold the second ramp in place. Using the previously marked outline, mark how much

needs to be cut away from the end of this ramp to fit next to the other ramp.

If you constructed the rest of the machine exactly according to

the dimensions in the plans, you can also use a template to mark the

mounting points and pilot holes on the bottom of the bowl.

If you constructed the rest of the machine exactly according to

the dimensions in the plans, you can also use a template to mark the

mounting points and pilot holes on the bottom of the bowl.

Cutting away part of the corner of the ramp to accomodate.

Cutting away part of the corner of the ramp to accomodate.

I ended up cutting away parts of both ramps to accommodate the fit.

I ended up cutting away parts of both ramps to accommodate the fit.

With the exit hole only slightly larger than the marbles, the ramps

drop the marbles straight down so that they hit their targets

fairly consistently.

With the exit hole only slightly larger than the marbles, the ramps

drop the marbles straight down so that they hit their targets

fairly consistently.

Next: Can drums

Back to Marble machine 2.1