Brian Sanders's marble machine

Brian Sanders writes:

Matthias,

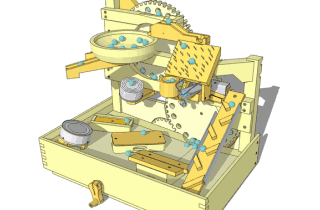

This is my marble machine I built based on the plans I purchased from you. I took more of a cabinet making approach to it, using different hardwoods, brass & aluminum throughout and redesigning certain elements such as the tuna can drums, etc. I used some small ball bearings I had lying around for the gears and crank to run on also. I wanted it to be sort of a functional “art piece”. So I thought you might enjoy seeing it (feel free to use it on your sight if you wish). I have a video on YouTube showing it in action http://youtu.be/_dpRI2snahA

I really enjoy your sight and talent and find myself quite envious of the fact you are able to do what you love for a living. Keep up the fine work and I look forward to every new project you publish.

Best wishes,

Brian Sanders

Burton, MI

USA

Wow, that machine is incredibly nicely built!

Looking closely at Brian's pictures (click any image to enlarge), I noticed that many elements I made from layers, such as various ramps were made from one piece. I noticed a CNC video among brian's videos and asked if he'd used his CNC.

His reply:

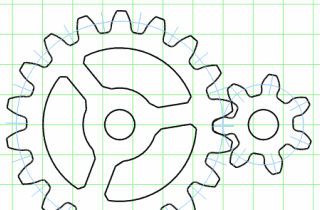

Yes I used my CNC for most everything on it including the flipflop gate. I used a CAD gear program to layout and cut real involute gears on the CNC also.

I figured if I was going to make something useless I might as well waste as much time as possible. LOL

That’s probably how old Rube Goldberg seen it too! I've attached a couple more pictures.

|

A video of the machine in action. For the impatient, the cranking starts at 0:40 in. |

Parts disassembled awaiting final finish

Parts disassembled awaiting final finish

“wooden tuna cans” made with canning lids.

“wooden tuna cans” made with canning lids.

Another video by Brian: making styrofoam gears on his CNC styrofoam cutter. And if you are asking how that could possibly be useful, you are probably missing the point :)

See also:

More marble machines on woodgears.ca

![]()

Christian's marble

Christian's marble Nancy Franks's marble machine

Nancy Franks's marble machine