I wanted to be able to convert between it being a stumpf fiddle or a

devil's stick so the devil's skull needed to be removable.

I wanted to be able to convert between it being a stumpf fiddle or a

devil's stick so the devil's skull needed to be removable.

a.k.a. Pogo-Cello, pogocello, Polka Cello, Poco Cello, stump fiddle,

boom-ba, boom bass, bumbass, Hum Strum, devil's violin, Teufel Stick

and others. Usually these are made from shovel handles, hoe handles,

pallet lumber, old ski's, cookie or cracker tin boxes... generally a

pretty casual construction. I thought I would try making one on purpose,

making as much of it myself as possible, and hopefully it wouldn't look

like something the dog dragged home. I don't really know how to play

one of these but I always wanted to make one. I wanted it to look well

constructed and to be something that wouldn't get beat up or fall

apart when it was used.

a.k.a. Pogo-Cello, pogocello, Polka Cello, Poco Cello, stump fiddle,

boom-ba, boom bass, bumbass, Hum Strum, devil's violin, Teufel Stick

and others. Usually these are made from shovel handles, hoe handles,

pallet lumber, old ski's, cookie or cracker tin boxes... generally a

pretty casual construction. I thought I would try making one on purpose,

making as much of it myself as possible, and hopefully it wouldn't look

like something the dog dragged home. I don't really know how to play

one of these but I always wanted to make one. I wanted it to look well

constructed and to be something that wouldn't get beat up or fall

apart when it was used.

I wanted to be able to convert between it being a stumpf fiddle or a

devil's stick so the devil's skull needed to be removable.

I wanted to be able to convert between it being a stumpf fiddle or a

devil's stick so the devil's skull needed to be removable.

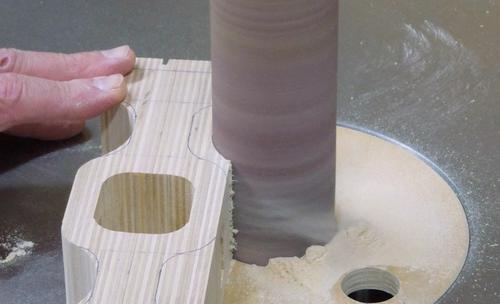

A square wood pipe was created from laminated scraps of plywood, which

would slide over the top of the main shaft.

A square wood pipe was created from laminated scraps of plywood, which

would slide over the top of the main shaft.

A nylon bolt locks it in place so it won't bounce off.

A nylon bolt locks it in place so it won't bounce off.

I wasn't able to find a long spring. I did obtain a ½ inch diameter

screen door spring, which was 18 inches long. I felt it would be too

difficult to stretch to a 36-inch length and would be much too tight.

I wasn't able to find a long spring. I did obtain a ½ inch diameter

screen door spring, which was 18 inches long. I felt it would be too

difficult to stretch to a 36-inch length and would be much too tight.

I tied it to the top of a stepladder and hung a bucket of water on the other end to stretch it to the required length. Then I gently heated it with a propane torch to cause the spring to relax. After it cooled I removed the bucket and measured the length. I did this a couple of times until the spring was 30 inches long. I guessed that a 30-inch length stretched to 36 inches would work for my purpose.

The spring is attached with two screw hooks.

The spring is attached with two screw hooks.

The hooks are screwed into Osage Orange tenons that are very strong

The hooks are screwed into Osage Orange tenons that are very strong

The area of the horn available for clamping was tapered and had a

soldered joint. The horn material is fairly thin and I did not want to

crush or distort the shape.

The area of the horn available for clamping was tapered and had a

soldered joint. The horn material is fairly thin and I did not want to

crush or distort the shape.

The wood clamp was made in two pieces.

The wood clamp was made in two pieces.

I wrapped the horn with plastic electrical tape and used epoxy to cast the shape of the horn.

The completed clamp holds firmly.

The completed clamp holds firmly.

Stainless steel food serving trays were used instead of the usual pie

pans or cookie boxes, which usually become pretty beat up and dented.

These stainless trays are fairly thick and much more durable. They

should take a pretty good beating.

Stainless steel food serving trays were used instead of the usual pie

pans or cookie boxes, which usually become pretty beat up and dented.

These stainless trays are fairly thick and much more durable. They

should take a pretty good beating.

A series of holes were punched around the outside edge and the trays joined with machine screws.

A nut between the trays provides an air gap so the sound can come out

and a lock nut holds the trays together.

A nut between the trays provides an air gap so the sound can come out

and a lock nut holds the trays together.

The tambourine was sized to fit around the main shaft and I used steel jungles.

The tambourine was made from ½" Baltic birch plywood.

I laminated plywood scraps to form the center support, which had a

center hole for the main shaft.

I laminated plywood scraps to form the center support, which had a

center hole for the main shaft.

Maple wood toy axle caps were used for decorative trim.

Maple wood toy axle caps were used for decorative trim.

A threaded rod coupler was epoxied into the bottom of the main shaft for attachment of the rubber bumper.

I cut a groove around the outside of the coupler so the epoxy would have

a better chance of holding it in place.

I cut a groove around the outside of the coupler so the epoxy would have

a better chance of holding it in place.

I used a laminated wood mounting bracket for the bell.

I used a laminated wood mounting bracket for the bell.

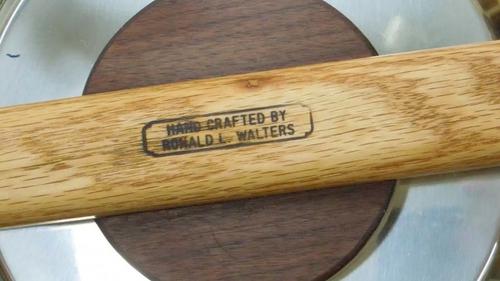

I used a wood branding iron to make my mark on the main shaft.

I used a wood branding iron to make my mark on the main shaft.

I experimented making wood percussion blocks. They all rang pretty well

but the rectangular blocks with the yellow Osage Orange faceplate were

the loudest. Osage Orange is a very hard wood.

I experimented making wood percussion blocks. They all rang pretty well

but the rectangular blocks with the yellow Osage Orange faceplate were

the loudest. Osage Orange is a very hard wood.

The main shaft is a lamination of two 60 inch lengths of oak with the

final dimensions 1-5/8" wide and 1-1/2" thick.

The main shaft is a lamination of two 60 inch lengths of oak with the

final dimensions 1-5/8" wide and 1-1/2" thick.

I cut a handhold at the top of the shaft the size of my hand, which provides a comfortable grip. This ended up weighing 9.3 pounds as the stumpf fiddle and 11.4 pounds as the devil's stick so I wanted a good grip.

All the parts were assembled and glued prior to application of linseed

oil to all wood surfaces.

All the parts were assembled and glued prior to application of linseed

oil to all wood surfaces.

There is a a video series on this sumpf fildle. Click play below to see all