So we picked some gear parameters that would be reasonably doable for both the bandsaw and the CNC machine.

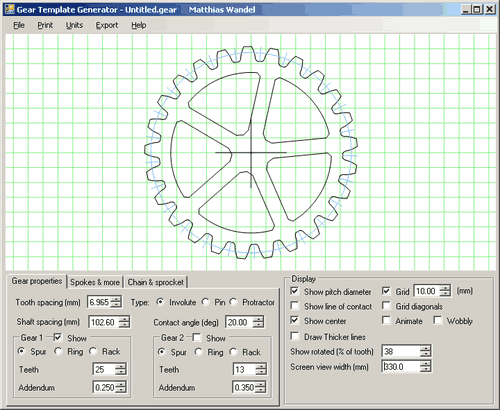

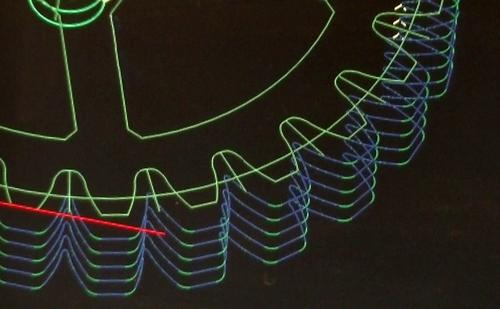

Here's designing it using my gear generator program.

So we picked some gear parameters that would be reasonably doable for both the bandsaw and the CNC machine.

Here's designing it using my gear generator program.

People keep suggesting that I should get into CNC. But I have always taken the position that CNC

wouldn't save me any time for what I do. In fact, I was pretty sure I could cut

out a gear faster on the bandsaw than most CNC hobby machines could.

People keep suggesting that I should get into CNC. But I have always taken the position that CNC

wouldn't save me any time for what I do. In fact, I was pretty sure I could cut

out a gear faster on the bandsaw than most CNC hobby machines could.

My friend Michael Grant already has a CNC machine, so I figured this would be an easy opportunity to put this to the test.

So we picked some gear parameters that would be reasonably doable for both the bandsaw and the CNC machine.

Here's designing it using my gear generator program.

So we picked some gear parameters that would be reasonably doable for both the bandsaw and the CNC machine.

Here's designing it using my gear generator program.

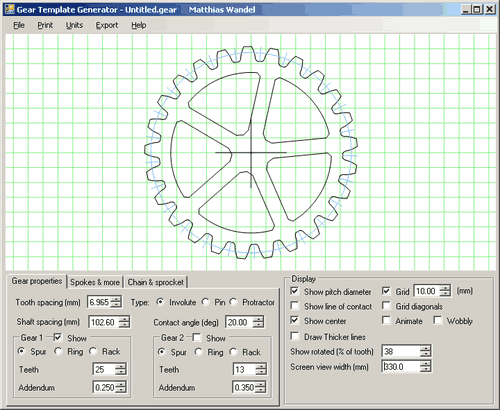

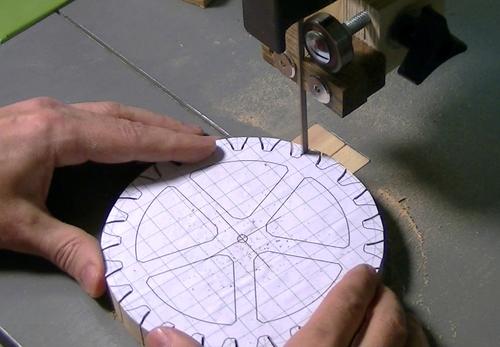

For bandsawing it out, we just printed the template straight from the program. I held a tape measure

to the 1 cm grid lines to verify that the printout was correctly scaled and free of distortion.

Inkjet printers, even cheap ones, are surprisingly accurate.

For bandsawing it out, we just printed the template straight from the program. I held a tape measure

to the 1 cm grid lines to verify that the printout was correctly scaled and free of distortion.

Inkjet printers, even cheap ones, are surprisingly accurate.

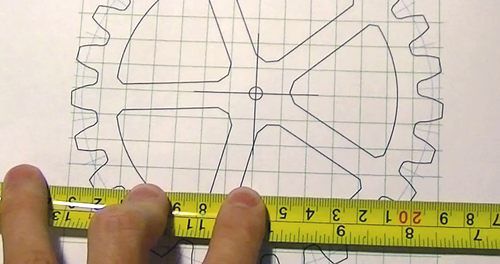

To set it up for milling on the CNC, a few more steps are needed.

Michael exported the gear as a DXF with polylines (new to version 3 of the program).

Next Michael used CamBam to turn the DXF outline into a

series of tool paths.

To set it up for milling on the CNC, a few more steps are needed.

Michael exported the gear as a DXF with polylines (new to version 3 of the program).

Next Michael used CamBam to turn the DXF outline into a

series of tool paths.

Even though the gear is a flat shape, it is nonetheless milled in 3D. Michael chose to mill the

3/4" (19 mm) thick plywood in five passes. With a 6 mm endmill, that depth can't be milled

in one go.

Even though the gear is a flat shape, it is nonetheless milled in 3D. Michael chose to mill the

3/4" (19 mm) thick plywood in five passes. With a 6 mm endmill, that depth can't be milled

in one go.

CamBam takes care of the tool path offsets quite nicely.

CamBam takes care of the tool path offsets quite nicely.

We also set the dedendum of the gear a bit deeper (by setting the "other gear" addendum larger in the gear program) so that the space between the gears would be a bit deeper.

Next the G-code file from CamBam was transferred onto the laptop by the CNC mill.

The laptop is running Mach to control the CNC.

Next the G-code file from CamBam was transferred onto the laptop by the CNC mill.

The laptop is running Mach to control the CNC.

Michael's CNC mill is an actual metal milling machine, as opposed to a CNC router. This means more precision, but also less range of motion than a typical CNC router would have.

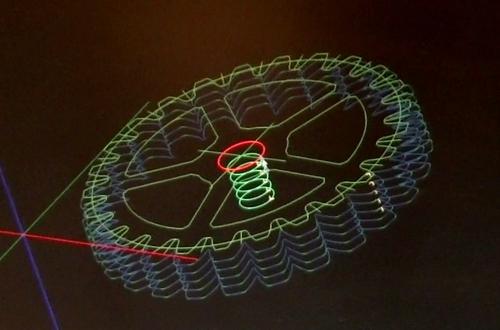

Here's milling it out. The endmill wasn't the sharpest, and I also forgot the "good" birch plywood

at home, so we used some cheap plywood. This didn't mill terribly cleanly.

Here's milling it out. The endmill wasn't the sharpest, and I also forgot the "good" birch plywood

at home, so we used some cheap plywood. This didn't mill terribly cleanly.

Not counting prep and setup time, the milling time was six minutes and forty seconds.

Next I cut out the gear on my 14" bandsaw, which I brought

along to Michael's shop. Easier to bring the bandsaw to his shop than the CNC to mine.

Along with the good plywood, I also forgot to bring the bandsaw blades. Oops! Fortunately,

it's a standard 93.5" blade, so we headed over to the nearest Canadian Tire and bought another blade.

Next I cut out the gear on my 14" bandsaw, which I brought

along to Michael's shop. Easier to bring the bandsaw to his shop than the CNC to mine.

Along with the good plywood, I also forgot to bring the bandsaw blades. Oops! Fortunately,

it's a standard 93.5" blade, so we headed over to the nearest Canadian Tire and bought another blade.

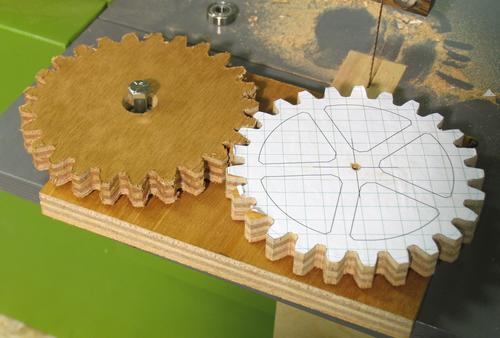

Even before I finished cutting, I had the feeling I'd lost this race. It took me 8 minutes and five seconds to cut out that gear. So the score was:

| CNC: | 6:40

| Bandsaw: | 8:05

| |

The bandsaw cut the cheap plywood quite cleanly. Having a brand new blade certainly didn't hurt.

The bandsaw cut the cheap plywood quite cleanly. Having a brand new blade certainly didn't hurt.

Placing the gears on top of each other, I could see that they were identical in shape and size, despite totally different processes. I mounted both of them on a board, and they meshed perfectly.

Not counting setup time, CNC definitely won. But the time spent on setting up easily exceeded cutting time. If you cut more than one gear, the setup time for subsequent gears drops, especially if the gears are identical. But for cutting one gear on rare occasions, the setup time is likely to far exceed the actual milling time.

I still haven't built a dedicated stand for the bandsaw. We just used a WorkMate to support

it in Michael's shop. I was a bit concerned that it might be a bit wobbly on the WorkMate,

but surprisingly, it was more steady than on the more sturdy planer stand I had been using in my shop.

I think that bandsaw and planer stand together have a resonant frequency too close to the

wheel rotation of the saw.

I still haven't built a dedicated stand for the bandsaw. We just used a WorkMate to support

it in Michael's shop. I was a bit concerned that it might be a bit wobbly on the WorkMate,

but surprisingly, it was more steady than on the more sturdy planer stand I had been using in my shop.

I think that bandsaw and planer stand together have a resonant frequency too close to the

wheel rotation of the saw.

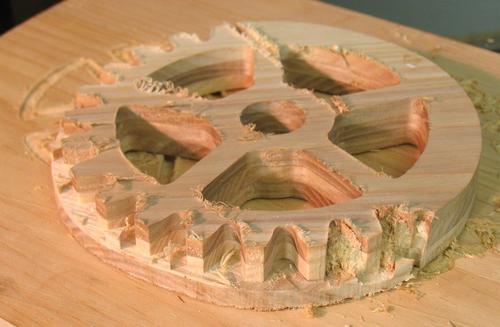

Michael wasn't that happy with how the CNC gear came out. He had some pieces of ash laminated together,

and figured that would make a nice gear, especially with spokes (which can't be cut on the bandsaw)

Michael wasn't that happy with how the CNC gear came out. He had some pieces of ash laminated together,

and figured that would make a nice gear, especially with spokes (which can't be cut on the bandsaw)

With the much harder wood, and a brand new 6 mm endmill, he set to work. That new endmill cut very cleanly in the hard ash wood.

Unfortunately, half way through the first pass of cutting the outside of the gear, the mill broke!

Oops!

Michael had mentioned that 3/16" (4.76mm) mill in the 5 mm chuck needed to be tightened down

hard to be secure. Not hard enough, apparently. I bandsawed a circle around the unfinished gear

to have a closer look.

Michael had mentioned that 3/16" (4.76mm) mill in the 5 mm chuck needed to be tightened down

hard to be secure. Not hard enough, apparently. I bandsawed a circle around the unfinished gear

to have a closer look.

What happened was that the mill wandered slowly downwards, so that it kept cutting deeper and deeper. What's amazing is that the mill was still cutting reasonably well even as it was cutting through two thirds of the ash wood in one pass. The mill only broke once it got deep enough that it could no longer clear the chips.

So this mill could probably have cut a gear like that in just two passes. With just the right setup, this mill could have beat me on the bandsaw by a much wider margin!

Not much use for a half-milled gear...

Not much use for a half-milled gear...

So the CNC machine was faster than I expected. What I didn't know was just how much preparation

is needed to cut a gear on the CNC machine. So for doing the occasional one-off gear,

I think I'm still better off making them on the bandsaw, even if I had a CNC machine.

When making shapes other than gears, if I design it in CAD,

I usually use my BigPrint program

to make 1:1 printouts, which I then also cut out on the bandsaw, similar to how

I did with the gear. For shapes with a lot of straight lines, there's much less

of an advantage to using CNC over regular power tools.

When making shapes other than gears, if I design it in CAD,

I usually use my BigPrint program

to make 1:1 printouts, which I then also cut out on the bandsaw, similar to how

I did with the gear. For shapes with a lot of straight lines, there's much less

of an advantage to using CNC over regular power tools.