Bandsaw 'zero clearance insert'

It's quite common to use a zero clearance insert

on a table saw. For a bandsaw, it's another matter though.

It's quite common to use a zero clearance insert

on a table saw. For a bandsaw, it's another matter though.

The problem with a bandsaw is that blade alignment is not nearly as precise. Blades are of different sizes and also often wander a little. The result is that a typical bandsaw insert has a very generous sized hole around the blade. A new "zero clearance" insert would probably soon have a rather large hole as well.

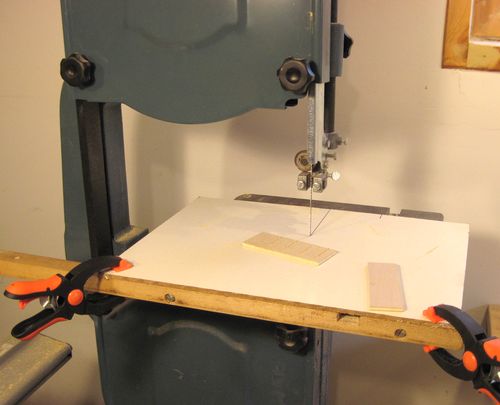

What I do to get the same effect as a zero clearance insert is to take a thin piece of plywood

or particle board, cut part-way

into it, stop, and clamp the piece in position on the table.

This makes for a flat surface that goes right up to the blade.

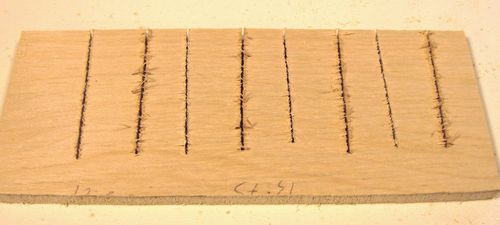

Pressing the stock down on the piece of plywood reduces tearout. The piece at left

has four cuts made with the piece pressed down on the plywood and four cuts made

with the regular insert. All cuts were made at the same speed.

The difference is not overly dramatic, but I think it's pretty obvious which cuts are which.

Pressing the stock down on the piece of plywood reduces tearout. The piece at left

has four cuts made with the piece pressed down on the plywood and four cuts made

with the regular insert. All cuts were made at the same speed.

The difference is not overly dramatic, but I think it's pretty obvious which cuts are which.

See also: Sharpening bandsaw blades

Back to the Shop tricks section