Whenever I make drawers, I just glue the floor flat on the bottom. But I often get

comments saying "wouldn't it be stronger if the bottom was placed in a groove,

or dado?"

Whenever I make drawers, I just glue the floor flat on the bottom. But I often get

comments saying "wouldn't it be stronger if the bottom was placed in a groove,

or dado?"

Whenever I make drawers, I just glue the floor flat on the bottom. But I often get

comments saying "wouldn't it be stronger if the bottom was placed in a groove,

or dado?"

Whenever I make drawers, I just glue the floor flat on the bottom. But I often get

comments saying "wouldn't it be stronger if the bottom was placed in a groove,

or dado?"

But I have often seen the wood break where the groove is, and with the glue as strong as the wood, I was pretty sure that a glued flat on drawer would be stronger, because the wood isn't weakened by a groove.

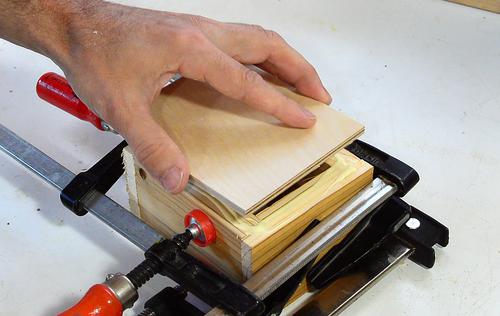

I figured it's time to put this to the test. So I made some small test boxes.

The boxes are 12x10 cm. Two with

the bottom in a groove, two with the bottom glued flat on.

I figured it's time to put this to the test. So I made some small test boxes.

The boxes are 12x10 cm. Two with

the bottom in a groove, two with the bottom glued flat on.

The corners of the boxes are just rabbet joined and glued. I didn't

use any nails.

The corners of the boxes are just rabbet joined and glued. I didn't

use any nails.

The boxes with the bottom in a groove need to be assembled with the bottom in place.

For the flat glued on bottoms, I can just glue it on after assembling

the box. Much easier.

For the flat glued on bottoms, I can just glue it on after assembling

the box. Much easier.

My test setup consists of my screw jack on a bathroom scale,

with a camera watching the scale. A "plunger" sits on top of the screw jack. The box

is placed upside down on the plunger. The plunger pushes on the "bottom" of the box

until it breaks.

My test setup consists of my screw jack on a bathroom scale,

with a camera watching the scale. A "plunger" sits on top of the screw jack. The box

is placed upside down on the plunger. The plunger pushes on the "bottom" of the box

until it breaks.

The box is held with screws from the sides. This holds it firm without

anything getting in the way of the bottom breaking off.

The box is held with screws from the sides. This holds it firm without

anything getting in the way of the bottom breaking off.

Breaking the first box. I cranked the jack up to 300 pounds, which is

the maximum that the scale will go to.

But aside from some creaking of my apparatus, nothing happened. So I kept cranking

until the scale read 150 again. With one and a half turns on the scale wheel,

this indicated 450 pounds.

Once at 450 pounds (200 kg), the reading didn't increase anymore. I figured this was

because the box was starting to yield, so kept cranking. Eventually,

the bottom flew off with a loud bang. The jack, and much of the apparatus jumped

from the sudden release of force.

Breaking the first box. I cranked the jack up to 300 pounds, which is

the maximum that the scale will go to.

But aside from some creaking of my apparatus, nothing happened. So I kept cranking

until the scale read 150 again. With one and a half turns on the scale wheel,

this indicated 450 pounds.

Once at 450 pounds (200 kg), the reading didn't increase anymore. I figured this was

because the box was starting to yield, so kept cranking. Eventually,

the bottom flew off with a loud bang. The jack, and much of the apparatus jumped

from the sudden release of force.

But then I saw the scale was quite bent. The jack was in the middle of the

scale during the test, but bounced to the side when the force was released.

The reason the force stopped increasing past 450 pounds was because the top

of the scale had bent enough to make contact with the bottom part. So there was probably

a lot more than 450 pounds of force.

But then I saw the scale was quite bent. The jack was in the middle of the

scale during the test, but bounced to the side when the force was released.

The reason the force stopped increasing past 450 pounds was because the top

of the scale had bent enough to make contact with the bottom part. So there was probably

a lot more than 450 pounds of force.

I took the top off the scale, straightened it out again, then put it back on.

The trickiest part was hooking up the little springs back on that hold the

top and bottom together.

I took the top off the scale, straightened it out again, then put it back on.

The trickiest part was hooking up the little springs back on that hold the

top and bottom together.

Standing on the scale, it read my weight correctly. So I figure it was still good.

Standing on the scale, it read my weight correctly. So I figure it was still good.

To take some load off the scale, I added a lever under the jack, which divides

the force, 80% to the fulcrum, 20% to the scale.

To take some load off the scale, I added a lever under the jack, which divides

the force, 80% to the fulcrum, 20% to the scale.

Testing the next sample. This one was also with the bottom in a rabbet, but without

any glue in the rabbet.

Testing the next sample. This one was also with the bottom in a rabbet, but without

any glue in the rabbet.

It failed at 800 pounds (360 kg). I can only assume that the force for the

glued rabbet joint I tested before was even more.

It failed at 800 pounds (360 kg). I can only assume that the force for the

glued rabbet joint I tested before was even more.

I was surprised just how much force it took to break these boxes!

Then testing the boxes with the bottom glued flat on. Both of these failed at about

600 pounds. So my theory that the glued flat on bottoms would be stronger was wrong.

Then testing the boxes with the bottom glued flat on. Both of these failed at about

600 pounds. So my theory that the glued flat on bottoms would be stronger was wrong.

I still think under the right circumstances, the bottom glued on flat would be stronger. But at the same time, if I used lesser quality plywood, where the bond between the laminations is not as strong, no matter how strong my glue is, the plywood itself would just de-laminate to pull off the bottom. So for those cases, the rabbeted bottom would always be stronger.

But I'll continue to glue my drawer bottoms flat on. My main reason is that it's easier,

and that it puts the drawer bottom further down, making more room in the drawer.

But I'll continue to glue my drawer bottoms flat on. My main reason is that it's easier,

and that it puts the drawer bottom further down, making more room in the drawer.

Looking at the drawers for my tool stand, these are at least 4x the length and width. Which means it should take about 2400 pounds to pop the bottom of the drawer. 2400 pounds is 1.1 metric tons. But even if I filled the entire volume of the drawers with solid lead, that would only weigh about 200 kilograms. So there is a lot of safety margin.

In the mean time, the drawer slides on this cabinet are rated for just 25 kilograms (55 pounds). Also these particular drawer slides wrap around the bottom of the drawers, which would also help to hold the bottom on.

An advantage of putting the drawer bottom in a dado is that the drawer would not slide

very well on a plywood bottom. But for these

workbench drawers, I still glued the plywood flat

on the bottom.

An advantage of putting the drawer bottom in a dado is that the drawer would not slide

very well on a plywood bottom. But for these

workbench drawers, I still glued the plywood flat

on the bottom.

I actually used some painted scrap plywood. I scraped the paint on either edge and glued

a strip of maple on. Maple is harder and slides better than spruce. That way I get a

harder sliding surface and still get to glue the drawer bottoms flat on the bottom.

I actually used some painted scrap plywood. I scraped the paint on either edge and glued

a strip of maple on. Maple is harder and slides better than spruce. That way I get a

harder sliding surface and still get to glue the drawer bottoms flat on the bottom.

Pocket hole strength

Pocket hole strength