The slinky machine - followup

It was my friend Eric Andrasi (who helped me shoot the air gun video) who originally came up with the slinky machine idea years ago. We talked about it over lunch from time to time, and I always teased him for not having built it yet. Eventually I concluded he'd never get around to building it, so it's fair game for me to build it.

The original idea was to also motorize it and add some speed control to make sure the machine runs at the same speed as the slinky. Eric's idea had been to have electrical contacts on the steps, and some sort of commutating setup to get the connection from the steps back to the base to determine where the slinky is for speed control. I always figured the electrical contacts would be too unreliable, and optical was the way to go.

But once I built the slinky machine escalator, I realized that keeping the slinky descending reliably was a much bigger challenge than anticipated. A straight run of 30 steps is already a challenge, so there's no point in automating it. Besides, if the machine is running and there's no one there to watch it, what's the point? And if someone is watching, that someone might as well be turning the crank.

The main challenges for keeping the slinky descending reliably are what

I like to call "stride" and "tracking". At left, two examples of unsuccessful

slinky tracking.

The main challenges for keeping the slinky descending reliably are what

I like to call "stride" and "tracking". At left, two examples of unsuccessful

slinky tracking.

Tracking is a matter of keeping the slinky from going off the side of the steps. The way I tackled this was to put a backer board on one side of the steps and angle the steps slightly towards the backer board. The backer board needs to be smooth enough that if the slinky does rub against it, it won't mess up the slinky's normal motion.

Another solution would be to make the steps much wider and curving upwards slightly towards the left and right edges. This would steer the slinky towards the center and eliminate the need for a backer board.

Controlling the stride was a bigger challenge.

Slightly tilting the steps or the whole machine will alter the stride a little.

Putting something just 1 cm thick under one end of the base was enough to

alter the stride to the point that the slinky would only descend a few

steps before tumbling.

Slightly tilting the steps or the whole machine will alter the stride a little.

Putting something just 1 cm thick under one end of the base was enough to

alter the stride to the point that the slinky would only descend a few

steps before tumbling.

To help regulate the stride I sanded a slight hollow into every step. When the slinky

lands closer to the nose, it's landing on an angled-back part of the step, shortening

its stride. If it lands towards the back the step is angled forward for a longer stride.

I also rounded the noses of all the steps so that the slinky can drag

over it if its stride is too short.

To help regulate the stride I sanded a slight hollow into every step. When the slinky

lands closer to the nose, it's landing on an angled-back part of the step, shortening

its stride. If it lands towards the back the step is angled forward for a longer stride.

I also rounded the noses of all the steps so that the slinky can drag

over it if its stride is too short.

I never got the machine to be terribly reliable. Getting the slinky to descend 100 steps without falling off or starting to tumble is always an accomplishment, like getting a high score in a game, except that I have no control once the slinky is launched.

I think a better solution would have been to make bigger steps and always rely on

the slinky dragging over the nose of the steps. My steps have 10 cm vertical and

horizontal per step. But the slinky can still barely walk down my basement

steps, which are 20 cm high and 22 cm deep. It takes a vigorous launch

to get the slinky going on those steps though.

I think a better solution would have been to make bigger steps and always rely on

the slinky dragging over the nose of the steps. My steps have 10 cm vertical and

horizontal per step. But the slinky can still barely walk down my basement

steps, which are 20 cm high and 22 cm deep. It takes a vigorous launch

to get the slinky going on those steps though.

The whole thing is very much a prototype / experiment. In fact, I also made the mistake of drilling the holes for the nails too big, so they fall out if the machine is laid on its side. But between the backer board on the back and the guide bearing on the front, the nails keep getting pushed back in as the chain goes around.

If I was building it again, I'd make the steps 11 cm vertical and horizontal and also a bit wider. But if I made the steps bigger the whole machine would be even bigger. I prefer my useless creations to be easyer to store. But it's these novel but useless contraptions that get people interested. If I build a dresser, that's very practical and useful, but it doesn't get the sort of attention that a jenga pistol or marble machine will get.

More fun but useless creations:

Back to my Woodworking website

Marble machines

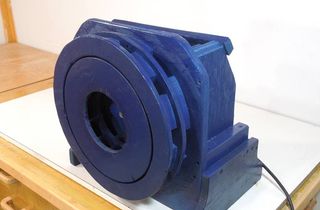

Marble machines Air raid siren

Air raid siren Wasp sucking machine

Wasp sucking machine Jenga pistol

Jenga pistol Marble shooting crossbow

Marble shooting crossbow Pen shaking contraption

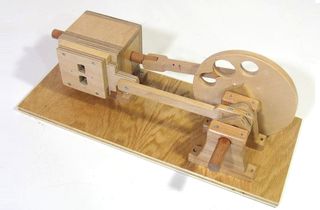

Pen shaking contraption Wooden air engine

Wooden air engine