I was working on compiling my belt sander build video series into one shorter video.

While I was at it, I figured it would be good to do an update on how the sander

has held up over the five years since I built it.

I was working on compiling my belt sander build video series into one shorter video.

While I was at it, I figured it would be good to do an update on how the sander

has held up over the five years since I built it.

I was working on compiling my belt sander build video series into one shorter video.

While I was at it, I figured it would be good to do an update on how the sander

has held up over the five years since I built it.

I was working on compiling my belt sander build video series into one shorter video.

While I was at it, I figured it would be good to do an update on how the sander

has held up over the five years since I built it.

I use this sander more than my other sanders, and I've used up five or six 6x48" sanding belts with it so far. It's given me little trouble.

The wooden bearings on the idler roller have held up perfectly, no sign of wear. and if they do eventually wear out, it will be easy enough to make new ones.

I didn't use inner tube on the drive roller because it's bigger and

I wasn't able to stretch an inner tube over it.

I didn't use inner tube on the drive roller because it's bigger and

I wasn't able to stretch an inner tube over it.

So I covered it with caulking instead. I was able to get a nice even coat on it by evening it with a piece of wood as I spun it.

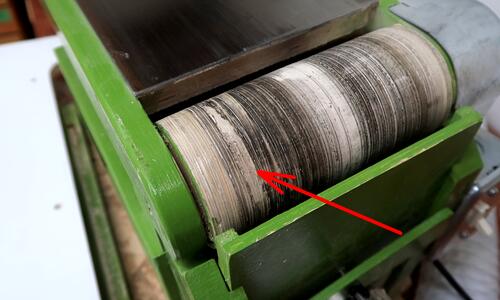

But inspecting it now, there's a small patch that came off. This part is at the level I usually have the table at when I do edge belt sanding, and sanding inside curves is always against the roller. So this part gets stressed more than the rest of the roller.

If I was building it again, I'd try a fat-bike inner tube for this roller. But back in 2016 when I built it, fat bikes were not common, so I hadn't thought of that.

I had to add tension to the belt one time by moving the motor a bit to the

left. It's now as far left as the mounting bolts allow, so if it becomes loose

again I'll have to buy a new belt.

I had to add tension to the belt one time by moving the motor a bit to the

left. It's now as far left as the mounting bolts allow, so if it becomes loose

again I'll have to buy a new belt.

The wooden pulley has not given me any problems.

The wooden pulley has not given me any problems.

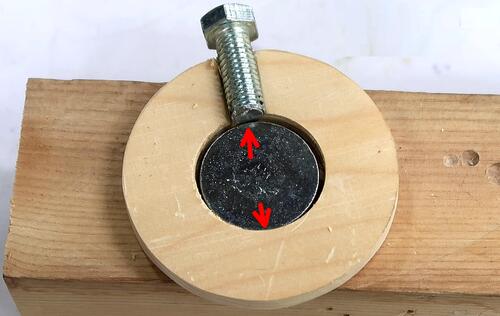

But inspecting it, I see cracks around the circumference. This is probably from getting hot when sanding for extended periods of time.

I used a wooden pulley to save $12, which is a good part of the cost of the plans, so my point was that just making the pulley out of wood could make up for most of the cost of buying the plans.

But wooden pulleys have the disadvantage that they don't conduct away the heat very well. If a machine stalls in a way that the wooden pulley spins on a belt that isn't moving, the belt won't carry away the heat, and the wooden pulley doesn't conduct it away very well either, so you end up with a smoking belt in short order.

This isn't a problem for the large wooden pulleys on my bandsaws because if the belt slips there, it always ends up slipping on the small motor pulley instead.

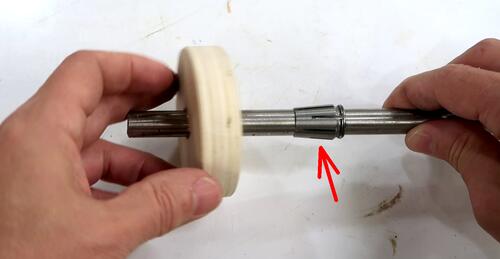

The other pulley is one with a 1/2" (12.7 mm) pulley on a 12 mm shaft. I made

a plastic shim from a 2 liter soda bottle to make up for the diameter difference

and get a tight fit. This hasn't given me any trouble.

The shim probably makes it better than a 1/2" pulley on a 1/2" shaft.

The other pulley is one with a 1/2" (12.7 mm) pulley on a 12 mm shaft. I made

a plastic shim from a 2 liter soda bottle to make up for the diameter difference

and get a tight fit. This hasn't given me any trouble.

The shim probably makes it better than a 1/2" pulley on a 1/2" shaft.

Pulleys with setscrews are

often troublesome.

There is usually a small bit of slack

between the shaft and the pulley. But with the setscrew tightened, the shaft presses

against the setscrew and against the opposite side. But nothing other than friction

keeps it from wiggling side to side, and as the belt pulls the pulley this way

and that way, it can keep wiggling back and forth until it becomes loose and wears the

hole larger. This Craftsman bandsaw suffered

from that problem to the point that the custom pulley it had was no longer usable.

Pulleys with setscrews are

often troublesome.

There is usually a small bit of slack

between the shaft and the pulley. But with the setscrew tightened, the shaft presses

against the setscrew and against the opposite side. But nothing other than friction

keeps it from wiggling side to side, and as the belt pulls the pulley this way

and that way, it can keep wiggling back and forth until it becomes loose and wears the

hole larger. This Craftsman bandsaw suffered

from that problem to the point that the custom pulley it had was no longer usable.

For larger industrial pulleys, the pulley is locked onto the shaft similar to how

a router holds the bit in the collet. A conical sleeve goes on the shaft, which fits

into a conical hole in the pulley. Then a plate is screwed to the pulley to press

the sleeve into the pulley, securely locking it in place.

For larger industrial pulleys, the pulley is locked onto the shaft similar to how

a router holds the bit in the collet. A conical sleeve goes on the shaft, which fits

into a conical hole in the pulley. Then a plate is screwed to the pulley to press

the sleeve into the pulley, securely locking it in place.

I have this belt sander on it's own dust collector (the

one I originally built for my

old belt sander)

I figured this would be a good time to check it and empty it out.

I have this belt sander on it's own dust collector (the

one I originally built for my

old belt sander)

I figured this would be a good time to check it and empty it out.

There was quite a lot of dust in it. I last emptied it a year and a half ago

in February 2020.

There was quite a lot of dust in it. I last emptied it a year and a half ago

in February 2020.

I started by sucking at the pleats with my

homemade cyclone dust collector. Then I had the better idea of just banging

it against the floor with the filter facing down. This got the rest of the

sawdust falling out of the filter.

I started by sucking at the pleats with my

homemade cyclone dust collector. Then I had the better idea of just banging

it against the floor with the filter facing down. This got the rest of the

sawdust falling out of the filter.

Cyclone dust collectors usually don't separate sanding dust all that well, but when sucking up a lot of dust at once, the cyclone separates most of it. Looking at the dust level in the collecting bucket, I sucked up 4-5 liters of fine dust.