I previously built this blower

and my two bucket cyclone to build a dust

collector. Now it's time to put the pieces together.

I previously built this blower

and my two bucket cyclone to build a dust

collector. Now it's time to put the pieces together.

I previously built this blower

and my two bucket cyclone to build a dust

collector. Now it's time to put the pieces together.

I previously built this blower

and my two bucket cyclone to build a dust

collector. Now it's time to put the pieces together.

Aside from the blower and cyclone, the dust collector will also need some

filters, which will fit inside this box. Here, showing the approximate

arrangement of parts that I'm aiming for.

Aside from the blower and cyclone, the dust collector will also need some

filters, which will fit inside this box. Here, showing the approximate

arrangement of parts that I'm aiming for.

What I still need is a manifold to connect the blower to the filters in the box.

The manifold will consist of another box behind the filter box, connecting the

filters to the blower inlet.

The manifold will consist of another box behind the filter box, connecting the

filters to the blower inlet.

There is a bit of a space constraint on the right side of the manifold. It has to connect to the blower inlet without interfering with the cyclone bucket that will be on the right side of the inlet.

Gluing the box together. I used a lot of clamps.

It was tempting to just brad nail it together, but I would still have

to glue it all together to make it airtight.

Gluing the box together. I used a lot of clamps.

It was tempting to just brad nail it together, but I would still have

to glue it all together to make it airtight.

If you want to build one and don't have that many clamps, you may have to glue it up in stages.

While waiting for the glue to dry, I'm attaching the mounts for the filter

to what will become the back of the filter box.

While waiting for the glue to dry, I'm attaching the mounts for the filter

to what will become the back of the filter box.

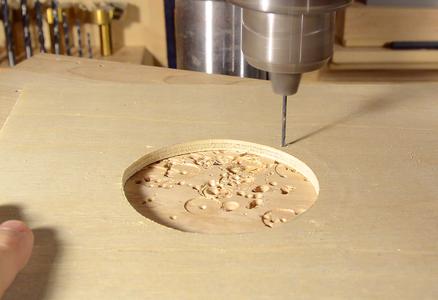

The filter connectors are conical, cut out by making a beveled cut along a circle on the bandsaw.

I tap the screws in the ring to mark where the pilot holes need to go, then drill these out and screw on the ring. Gluing it on would be better, but if I change my mind on what style of filter to use later, I want to still be able to remove them.

The filters have a hole in the end. I made a piece of wood to fit in

the holes and also support the filters vertically.

Air from the cyclone comes in through an ABS elbow from the top.

With any cyclone, if it fills with sawdust because the collection

bucket is full, dust ends up passing straight through.

This can get the filters all clogged up with shavings. To prevent that

from happening, I made a screen to go just above them. That way,

if the cyclone gets full of shavings, this area will

get filled and blocked without getting the filters full of shavings.

I also added two small spacer blocks to the inside of the box

to help support the relatively thin plywood against the suction.

Note that the filter box extends beyond the box that forms the manifold (left

side of the picture). The plywood that is the top of the manifold box

extends a bit past the manifold for this purpose.

Because the front of the blower is not very thick (just 1 cm), I'm using a lot

of short screws so I don't get protrusions into the blower housing.

I laid out and drilled the locations of these screws before gluing the manifold

box together. I also drilled pilot holes in the blower housing. I transferred

the hole locations to the blower by laying the back of the manifold onto the blower

housing (before assembling the manifold), placing screws in the screw holes

and tapping them with a mallet.

The pipe connects to the flange for the top of the filter box with

three screws from the inside.

I found I could get a fairly square cut in the ABS by laying it on

a drill press vise and sliding that along the bandsaw, using my

right hand to guide the edge of the vise so it stays flush with

the table edge.

I don't yet have a way to attach the cover for the filter box yet, but

with the blower turned on, it's held on by vacuum.

Now I still need to attach the cyclone to it, make a wheeled base for

it, paint it, add a switch, and other minor details.

More on that next week.

With the back panel temporarily clamped to the filter box, checking the

fit of the filters.

With the back panel temporarily clamped to the filter box, checking the

fit of the filters.

With the previous glue-up of the manifold box done, preparing to glue

on the cover. This cover will also form the back of the filter box.

With the previous glue-up of the manifold box done, preparing to glue

on the cover. This cover will also form the back of the filter box.

Cover glued and clamped, waiting for the glue to dry again.

Cover glued and clamped, waiting for the glue to dry again.

Now gluing the main filter box onto the manifold.

Now gluing the main filter box onto the manifold.

I added a strip of felt around the outlet hole on the manifold to make

for a better seal to the blower.

I added a strip of felt around the outlet hole on the manifold to make

for a better seal to the blower.

Screwing the manifold to the blower.

Screwing the manifold to the blower.

Some of the screws are only accessible through the inside of the filter housing,

through the holes for the filter mounts.

Some of the screws are only accessible through the inside of the filter housing,

through the holes for the filter mounts.

For extra hold, I also added some screws to the corners. I had to drill

holes through the back layer of the blower housing to be able to get at

these with a screwdriver.

For extra hold, I also added some screws to the corners. I had to drill

holes through the back layer of the blower housing to be able to get at

these with a screwdriver.

I made the connection from the cyclone to the blower out of 3" ABS pipe.

I made the connection from the cyclone to the blower out of 3" ABS pipe.

Here placing the collection bucket against the blower and filter box

and checking where the flange needs to end up, then screwing it on.

Here placing the collection bucket against the blower and filter box

and checking where the flange needs to end up, then screwing it on.

Now installing the filters again, and the filter holder.

Now installing the filters again, and the filter holder.

And testing it. Works quite nicely.

And testing it. Works quite nicely.