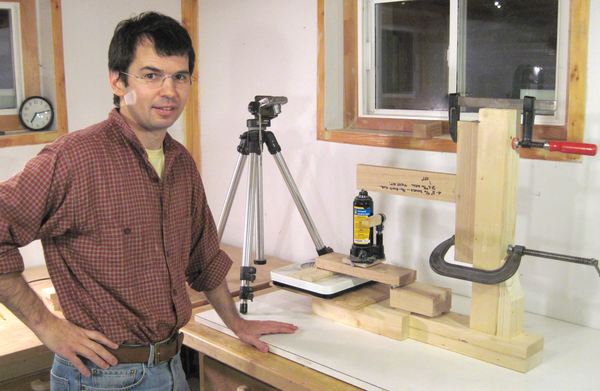

The specimens, as sent to me

I then went on to say that the multiple dowel joints I used were similar to those produced by a particular doweling jig. This solicited an email from the makers of the jig pointing out that I hadn't actually used their jig, and that the joint geometry was not the same as theirs. They asked that I remove all references to the name of their product, and that in the event that my page should show up in a prominent position in searches for their product, their lawyer would take the issue up directly with Google, Yahoo, and other search engines.

Having little stake in the matter, I removed all references to their jig and company name. If I was wiser, that would have been the end of the story.

However, a few weeks later, I noticed on a public forum that discussed my tests the following statement from one of the people working for the makers of the dowel jig (which shall remain unnamed in this article):

The specimens, as sent to me |

I would have much preferred the mortised piece to be fairly thick, but the makers of the dowel jig insisted that it be 3/4" (18mm). I figured this would not leave that much wood on either side of the mortise, so I suggested using a 1/4" wide mortise against the 3/8" wide dowels, which the makers of the dowel jig agreed to. I'm pretty sure that the amount of remaining material, and likely my choice of 1/4" tenons over 3/8" tenons turned out to probably be a key factor in how the tests turned out. The makers of the dowel jig always test against a 3/8" tenon in 3/4" stock.

We decided to do tests in 3 7/8 x 3/4" (72 x 18 mm) red oak. We settled for

a four dowel joint, with one inch dowel penetration. The dowel joints

were prepared by the makers of the dowel jig and sent to me. They also sent some

blank boards of the same stock for me to make mortise and tenon joints in. Wood can

vary considerably, but with all the wood from the same source, hopefully this

source of variability would be less.

We decided to do tests in 3 7/8 x 3/4" (72 x 18 mm) red oak. We settled for

a four dowel joint, with one inch dowel penetration. The dowel joints

were prepared by the makers of the dowel jig and sent to me. They also sent some

blank boards of the same stock for me to make mortise and tenon joints in. Wood can

vary considerably, but with all the wood from the same source, hopefully this

source of variability would be less.

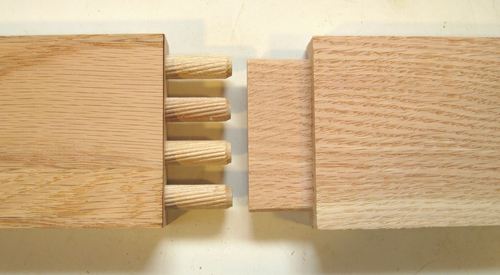

I used the blank boards to make mortise and tenon joints with a comparable geometry.

1" penetration, and a tenon width of 2 3/8". I chose a tenon thickness of 1/4". With the stock

only 3/4" thick, it didn't make much sense to cut away that much of the material

to make the mortise.

The dowels used were pre-compressed hardwood dowels, 2" in length, with the dowel penetrating into either piece by 1".

Given the width of the stock, it might have made more sense to make a deeper joint, but the only other option for the pre-compressed dowels was to use 4" dowels. That would have meant 2" in either side, but I didn't have a long enough 1/4" router bit to cut comparable mortises. They wanted to keep the joints symmetrical, so using unequal penetration on either side wasn't an option.

The glue we used for the tests were WeldBond, and ProBond.

|

Because my bathroom scale only reads up to 300 pounds, I split the force from the jack between two points, so that only half of the force would press on the bathroom scale. Each pound read by the scale would thus be two pounds applied to the joint. With the pivot 1 foot from the joint surface, each bathroom scale pound works out to two foot-pounds.

This pivot at the top of the jack ensured the force was applied at the right distance |

My jig applied the force one foot from the joint, whereas the jig used by the makers of the dowel jig applies a the force very close to the joint (roughly 2"), resulting in stress on the joint that has a substantial shear-force component.

Real furniture joints tend to get stressed by more moderate forces applied at

greater distance, so I like my tests more. Think of

the stresses on the joint between the piece that makes up the chair back and legs

and the part holding the seat when a fat guy leans back on a chair. The stress

is from force applied a fair distance from the joint itself.

For each joint tested, the wood cracked open before the joint itself began to separate |

Because the vertical piece was relatively thin with respect to the joint,

each joint initially split open on the vertical piece before the

joint itself started to yield.

This problem could have been avoided by using a much thicker vertical

piece, as I had done in my previous tests,

but the makers of the dowel jig wanted both pieces to be 3/4" thick.

A dowel joint, after testing. Much like the joint in the previous image, this joint initially cracked open in the vertical member. Once the force was removed, this crack completely closed up again

A failed mortise and tenon joint. A remnant of the gap is still visible,

though it had mostly closed once the force was removed.

A failed mortise and tenon joint. A remnant of the gap is still visible,

though it had mostly closed once the force was removed.

|

As it was, overall, the dowel joints had a higher force for the initial cracking open, but a slightly lower force to subsequently separate the joint.

It's debatable which force is the actual point of failure of the joint. The post splitting open certainly is a point of failure. But if the force was removed after that point, the gap that opened up closed again, and nobody would be the wiser that this joint had actually "failed". The joint shown at left had actually cracked open much like the joint in the previous image. But once the dowels let go, that crack closed up again, so that crack is not even visible in the photo.

But the secondary breakage is also iffy. By the point that the dowels or tenon actually let go from the wood they were in, everything was quite deflected. There was also variability where the wood actually split open. The closer it split to the joint, the less wood there was left to hold. So using the final separation force may not be that realistic either.

It always amazes me that when woodworking magazines do joint tests, that they don't go into this sort of thing. A nice final number certainly sounds better than to muddy the water with a lot of analysis and discussion. I suspect tests done in woodworking magazines often have similar issues, but I imagine they figure people just want an answer, and not a lot of discussion about the validity of the results.

I figured I should present both the force of the initial cracking open, and the force required for final separation in my results, but this is where I started running into problems with the manufacturer.

The makers of the dowel jig wanted only the forces of the initial cracking open to be considered as the results and all other numbers to be omitted from the report, which would make the dowel joint the winner. I didn't feel that this would be realistic. It's normal to test a joint at least to the point of maximum force. The initial cracking open wasn't even breaking the joint itself, so was it even a measure of joint strength? Certainly, the cracking open force, on average, was larger for the dowel joints. This could be because the dowel joints cut away a bit less of the wood of the vertical piece, thus weakening it less.

Of course, we each had out own motivations and biases. The makers of the dowel jig take pride in stating that their joints are stronger than mortise and tenon joints and were probably looking for another test to confirm this assertion. I don't sell any dowel jigs, but I do make a little bit of money selling slot mortising machine plans and a tenon jig plans. so I wasn't particularly interested in making mortise and tenon joints look bad.

And so perhaps it's no surprise that when the makers of the dowel jig test their joints against mortise and tenon joints, the dowel joint wins, whereas when I test it, the mortise and tenon joint does a little better.

Of course, if I wanted to, manipulating the results would be trivially easy.

With the variability of wood, all one has to do is select the right pieces and

the right results to make the results conclusively go one way or the other.

| Joint | Glue | Wood splits force Pullout after | wood splits Maximum force

| Dowel | ProBond | 135 | 80 (excluded) | 135

| Dowel | ProBond | 115 | 110 | 115

| Dowel | WeldBond | 105 | 105 | 105

| Dowel | WeldBond | 130 | 135 | 135

| Average dowel: | 121 | 116 | 123

| Mortise & Tenon | WeldBond | 95 | 140 | 140

| Mortise & Tenon | ProBond | 110 | 135 | 135

| Average 1/4" mortise & tenon: | 103 | 138 | 138

| | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

It's hard to come to any definite conclusion with these numbers. Given the variation

in joints of the same type, the difference in failure force is not enough to

draw any statistically significant conclusion. And then the question is,

which is the number that counts? One could declare either joint type the winner.

I made two bandsaw cuts to the left and right of a mortise and tenon joint, at which point,

what was left just fell apart along the line that the wood that previously cracked open.

I made two bandsaw cuts to the left and right of a mortise and tenon joint, at which point,

what was left just fell apart along the line that the wood that previously cracked open.

And here's a dowel joint split open the same way. It split just shy of

the ends of the dowels. The tapered ends of the dowels didn't provide

useful gluing surface, so the split is a little bit back from the tips of the dowels.

The mortise and tenon joint has the advantage there, with the glue surface extending

all the way into a flat-bottomed hole.

And here's a dowel joint split open the same way. It split just shy of

the ends of the dowels. The tapered ends of the dowels didn't provide

useful gluing surface, so the split is a little bit back from the tips of the dowels.

The mortise and tenon joint has the advantage there, with the glue surface extending

all the way into a flat-bottomed hole.

I offered to run another set of tests with 3/8" wide tenons, but by this point, the makers of the jig didn't want to have much to do with these tests anymore. They also pointed out that they had used inferior quality dowels for two of the tests and insisted that the two dowel joints that failed at lower forces be omitted from the results. I was not amused. Why would they deliberately use inferior quality dowels, and why would they only tell me they did so after the tests were run?

This all struck me as a little strange. The dowel joints had actually performed quite well in my tests, nearly as well as the mortise and tenon joints. Repeatability in wood joint testing is generally poor, and with all the variability, it's hard to say for sure that one joint is better than the other. But the makers of the dowel jig insisted that their joints are always stronger. We couldn't come to an agreement about the interpretation of the results and I was unwilling to omit the samples and separation forces that suggested mortise and tenon joints were stronger. And so, to be safe, I figure it's best if I keep the makers of the dowel jig anonymous.

Given all this, I was glad that I only used some joints they sent me, as opposed to accepting one of their fancy dowel jigs from them. My thinking is that working with any manufacturer for review purposes puts one in a difficult position, especially if one happens to review a jig one doesn't like. So while corporate sponsorship would be nice thing to have at times, life is much simpler without it. At the rate I'm going, I doubt manufacturers are inclined to approach me :)

What type of joint performs best will vary with a lot of factors. If this test had been done with a very soft wood, the dowel joint would probably have an advantage because four hardwood dowels would probably be stronger than a softwood tenon.

Either joint could be improved on, but in different ways. The dowel joint could have been made much deeper for a stronger joint. The tenon joint could have been made a little bit deeper without having to worry about what size pre-made dowels are available. It most certainly could have been made the full width of the material. Mortise and tenon joints also offer a bit more flexibility, because one doesn't have to worry about sizing the joint for a specific number of dowels.

Ultimately, when you build furniture, it comes down to what you are set up to do. If you have a doweling jig, a dowel joint can be faster. If you have good mortise and tenon equipment, the mortise and tenon is probably quicker. Both joint types are strong enough for most applications, so it's best to base your choice on how fast and accurately you can make them. I prefer mortise and tenon joints more - with fewer surfaces, they were much faster to glue up. Oh, did I mention I might be biased?

Self centering dowel jig

Self centering dowel jig