Hector's router lift

This article is about Hector's router lift, which is part of his table saw workstation

Opening the top of the table saw workstation reveals the

built in router lift on the right side.

Opening the top of the table saw workstation reveals the

built in router lift on the right side.

The up-down carriage in place. This photo shows the router lift

still under construction.

The up-down carriage in place. This photo shows the router lift

still under construction.

This is the router cabinet module with the other part

of the slide in place (removed from the cabinet).

Since these slides can be separated it is

easy to take out the carriage for maintenance and cleaning.

Changing router motors only requires loosening the two 5/16"

Allen cap-head screws. No need to take out the

carriage.

This is the router cabinet module with the other part

of the slide in place (removed from the cabinet).

Since these slides can be separated it is

easy to take out the carriage for maintenance and cleaning.

Changing router motors only requires loosening the two 5/16"

Allen cap-head screws. No need to take out the

carriage.

A view of the carriage with the slides screwed in place.

The hardwood runners are carefully planed to exact thickness to

counteract any slop of the carriage within the cabinet. The long

slot at the left is for the height locking mechanism. A thick

aluminum plate is used to mount the router. It has a 43mm hole

for the Eltos but a different plate can be used to mount the 71mm

Bosch. Even a 89mm router motor would eventually fit with a suitable

plate.

A view of the carriage with the slides screwed in place.

The hardwood runners are carefully planed to exact thickness to

counteract any slop of the carriage within the cabinet. The long

slot at the left is for the height locking mechanism. A thick

aluminum plate is used to mount the router. It has a 43mm hole

for the Eltos but a different plate can be used to mount the 71mm

Bosch. Even a 89mm router motor would eventually fit with a suitable

plate.

A dust cover removed. Made from scrap hardwood, 1/8"

hardboard and aluminum sheet. This cover protects the drawer slide

from the router dust.

A dust cover removed. Made from scrap hardwood, 1/8"

hardboard and aluminum sheet. This cover protects the drawer slide

from the router dust.

A view of the controls. The hand wheel raises or lowers

the router. The star knob locks the carriage in place for working.

The hole was a dust collection port. It did not work as expected

so it will be eventually plugged.

A view of the controls. The hand wheel raises or lowers

the router. The star knob locks the carriage in place for working.

The hole was a dust collection port. It did not work as expected

so it will be eventually plugged.

A view of the bridge in its operating position. The

carriage has been lifted and locked in the bit changing position

to allow a better photo. At right, one of the two springs that

pull the carriage down against the bearings.

A view of the bridge in its operating position. The

carriage has been lifted and locked in the bit changing position

to allow a better photo. At right, one of the two springs that

pull the carriage down against the bearings.

The bridge unit with ball bearings. Note the 3/8"

hole for the threaded rod that pushes/pulls the bridge to lift

the carriage.

The bridge unit with ball bearings. Note the 3/8"

hole for the threaded rod that pushes/pulls the bridge to lift

the carriage.

The carriage in working position. When the bridge is

pulled or pushed, the bearings move along the slope and lift or

lower the carriage. The springs keep the slopes always in contact

with the bearings. Operation is very smooth and flawless. One

turn of the hand wheel raises the bit 1mm, so it is easy to control

and even return to a previous setting. The slopes are made out

of 1/4" hardboard.

The carriage in working position. When the bridge is

pulled or pushed, the bearings move along the slope and lift or

lower the carriage. The springs keep the slopes always in contact

with the bearings. Operation is very smooth and flawless. One

turn of the hand wheel raises the bit 1mm, so it is easy to control

and even return to a previous setting. The slopes are made out

of 1/4" hardboard.

The router in bit changing position. The table was

lifted for the photo but bit changing can be accomplished from

the top, with the table in place. A handle is used to pull the

carriage up. It is then locked and a shop-made plate used to

lock the spindle. Only a single wrench is then required for

the bit change. The small dark boxes with a small spring attached

are dust covers for the slides.

The router in bit changing position. The table was

lifted for the photo but bit changing can be accomplished from

the top, with the table in place. A handle is used to pull the

carriage up. It is then locked and a shop-made plate used to

lock the spindle. Only a single wrench is then required for

the bit change. The small dark boxes with a small spring attached

are dust covers for the slides.

The spindle locking plate slips around the shaft of the router

and one of the mounting screws to lock the spindle during

bit changes.

The spindle locking plate slips around the shaft of the router

and one of the mounting screws to lock the spindle during

bit changes.

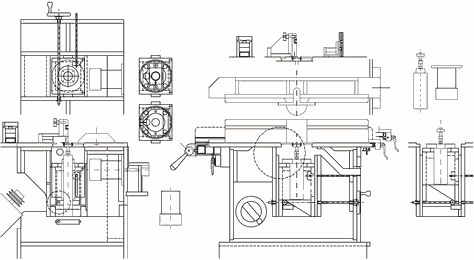

There are also some CAD drawings of the router lift.

There are also some CAD drawings of the router lift.

You can download these drawings:

PDF version of table saw drawings

DWG (AutoCAD) version of table saw drawings

Please note that the drawings are 2D plan views, not 3D models.

More about Hector's table saw workstation

See also:

More about Hector's table saw workstation |

Home made tilting Router lift, with gears! |

Dejan Kovac's router table |

Router table saw extension |

John Heisz's router table |