I wanted to try making a fan blade for a 1 HP motor I have kicking around

just to see how hard it would blow. The fan blade is cut out

of a piece of 2x4 lumber.

I wanted to try making a fan blade for a 1 HP motor I have kicking around

just to see how hard it would blow. The fan blade is cut out

of a piece of 2x4 lumber.

I wanted to try making a fan blade for a 1 HP motor I have kicking around

just to see how hard it would blow. The fan blade is cut out

of a piece of 2x4 lumber.

I wanted to try making a fan blade for a 1 HP motor I have kicking around

just to see how hard it would blow. The fan blade is cut out

of a piece of 2x4 lumber.

I start by making two diagonal cuts from each end of the 2x4

against a fence.

I start by making two diagonal cuts from each end of the 2x4

against a fence.

Then with the fence removed, I finish those cuts by curving out

of the wood.

Then with the fence removed, I finish those cuts by curving out

of the wood.

Then lots of sanding to smooth the surface and also to correct for imbalance

in the blade. I also rounded the leading and trailing edges of the blade.

Then lots of sanding to smooth the surface and also to correct for imbalance

in the blade. I also rounded the leading and trailing edges of the blade.

I cut a sort of "keyway" into it with a jigsaw, then hammered it onto the shaft

of my motor. I drilled a 15 mm hole for the 5/8" (15.87 mm) shaft, so it was

a very tight fit.

I cut a sort of "keyway" into it with a jigsaw, then hammered it onto the shaft

of my motor. I drilled a 15 mm hole for the 5/8" (15.87 mm) shaft, so it was

a very tight fit.

Then hammering in a pin between the notch in the blade and the keyway in

the motor shaft.

Then hammering in a pin between the notch in the blade and the keyway in

the motor shaft.

I screwed the motor down onto a big piece of wood to hold it down.

I didn't want to repeat the motor going flying

like when I built my air raid siren.

I screwed the motor down onto a big piece of wood to hold it down.

I didn't want to repeat the motor going flying

like when I built my air raid siren.

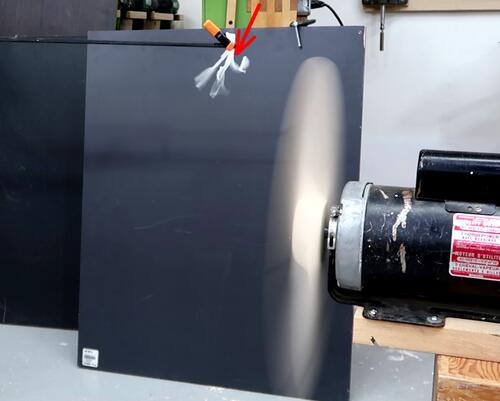

Plugging it in for the first time. My power meter was reading 3000 watts

before the breaker blew. The blade was too long and needed too much power.

Plugging it in for the first time. My power meter was reading 3000 watts

before the breaker blew. The blade was too long and needed too much power.

Marking a shorter radius on it with my beam compass

Marking a shorter radius on it with my beam compass

Then cutting it in place. It's too much trouble to take the blade off the

motor. I had to repeat this a few times until the power consumption

was reduced to 1.4 kW. At 1.4 kW, the motor was only a little bit overloaded.

Then cutting it in place. It's too much trouble to take the blade off the

motor. I had to repeat this a few times until the power consumption

was reduced to 1.4 kW. At 1.4 kW, the motor was only a little bit overloaded.

Testing the air speed, over 18 meters per second some distance away from

the blower. It's probably about 2.2 cubic meters per second,

or about 5000 cfm.

Testing the air speed, over 18 meters per second some distance away from

the blower. It's probably about 2.2 cubic meters per second,

or about 5000 cfm.

I tested it blowing against a normal oscillating fan. It stopped the fan

and it started to reverse, but then the fan got blown off the box it was on.

After weighing it down, I tried again, and it spun the fan backwards

as fast as it had been going forwards before, even though it was on

and set to maximum power.

I tested it blowing against a normal oscillating fan. It stopped the fan

and it started to reverse, but then the fan got blown off the box it was on.

After weighing it down, I tried again, and it spun the fan backwards

as fast as it had been going forwards before, even though it was on

and set to maximum power.

I mounted the motor on a hand truck for trying it out. It could do a good job

of cleaning scrap wood off the floor.

I mounted the motor on a hand truck for trying it out. It could do a good job

of cleaning scrap wood off the floor.

Then trying it outside. Leaves just went flying. Every once in a while there

was a little pop as a leaf got sucked into the fan and was struck by the blade.

Then trying it outside. Leaves just went flying. Every once in a while there

was a little pop as a leaf got sucked into the fan and was struck by the blade.

It was tiring to operate though. Not so much because the motor is heavy,

but because of the need to push forward against the fan's thrust.

It was tiring to operate though. Not so much because the motor is heavy,

but because of the need to push forward against the fan's thrust.

As a leaf blower, it wasn't that effective, because it wasn't practical to direct the air stream at or under specific leaves to dislodge them. And it kicked up such a storm, the leaves just went everywhere.

Also, it wasn't a very focused air stream. Even this small blower will get my annemometer to 24 meters per second if it's aimed straight at the anemometer. But when blowing leaves, one usually just aims at the leaves that need dislodging, so it doesn't need to be a wide stream.

On the driveway, I didn't even need to get near the leaves to move them!

It would be perfect for clearing the driveway, but the wind normally takes

care of that.

On the driveway, I didn't even need to get near the leaves to move them!

It would be perfect for clearing the driveway, but the wind normally takes

care of that.

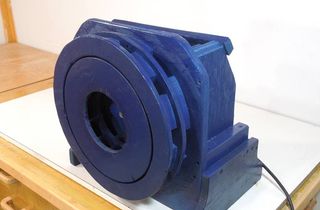

About half the comments on the video were "You should put a cowling around

the fan to make it more efficient". But from my experience, a fan produces

a fairly directed jet of air that a cowling wouldn't help much. To

illustrate my point, I figured I'd make a video to demonstrate this,

showing how the fan and the air stream doesn't so much diverge but sucks

more air in from the sides — something I had demonstrated back

in 2012 with my venturi effect experiments

About half the comments on the video were "You should put a cowling around

the fan to make it more efficient". But from my experience, a fan produces

a fairly directed jet of air that a cowling wouldn't help much. To

illustrate my point, I figured I'd make a video to demonstrate this,

showing how the fan and the air stream doesn't so much diverge but sucks

more air in from the sides — something I had demonstrated back

in 2012 with my venturi effect experiments

Surprising findings were that the area in front of the fan actually has a fair bit of vacuum, which I believe is what holds together the spinngin air stream that comes from the fan. I also noiced the air stream seemed to be dropping to the floor, then realized this is because the jet of air keeps sucking in more air from the sides and essentially sucked itself to the floor. This effect is known as the coanda effect. I found these experiments fascinating. But with my YouTube channel not being a science focused channel, these scienc type videos usually don't do that well on it.

Having demonstrated that a cowling with this fan probably wouldn't help, some sort of a nozzle in front of a centrifugal fan (which are better at producing more pressure but less airflow) can help, as demonstrated in this video

The Venturi effect (2012)

The Venturi effect (2012) Building an air raid siren (2012)

Building an air raid siren (2012) Building a box fan (2013)

Building a box fan (2013) Blower impeller experiments (2017)

Blower impeller experiments (2017) Workshop air cleaner (2016)

Workshop air cleaner (2016) How AC induction

How AC induction Mini tornado experiment (2012)

Mini tornado experiment (2012)