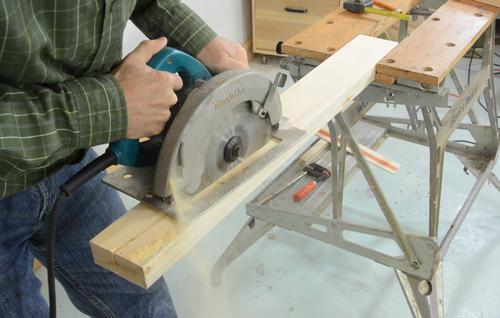

I'm using minimal tools for this build: A circular saw, hand drill,

I'm using minimal tools for this build: A circular saw, hand drill,doweling jig, some clamps, and a few other bits.

This simple crosscut jig I'm using is just two pieces of wood

This simple crosscut jig I'm using is just two pieces of wood

glued at a right angle.

I previously covered building a table of this design in 2008, but did not make a video of it. So when I needed another table, this time I made video. I did a few things different this time, so I figured it's worth covering in text again.

I'm using minimal tools for this build: A circular saw, hand drill,

I'm using minimal tools for this build: A circular saw, hand drill,

This simple crosscut jig I'm using is just two pieces of wood

This simple crosscut jig I'm using is just two pieces of wood

glued at a right angle.

The jig is clamped to the wood being cut. Works elegantly.

The jig is clamped to the wood being cut. Works elegantly.

For a sleeker look, I decided to taper the legs of this table,

For a sleeker look, I decided to taper the legs of this table,

just a freehand cut, following a pencil line.

The saw cut wasn't perfectly straight and the saw leaves a rough

The saw cut wasn't perfectly straight and the saw leaves a rough

surface, so I smoothed the legs with a hand plane. The work-mate,

with it's vise, and foot step for holding it down is ideal for this.

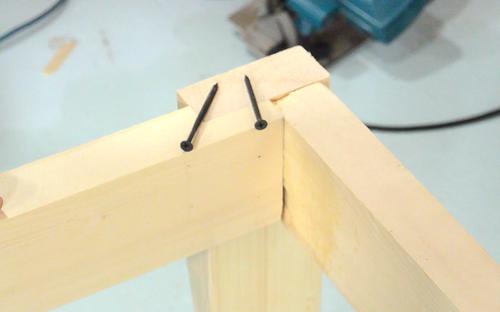

I need to assemble two frames that look like this.

I need to assemble two frames that look like this.

I'm going to join the legs with four dowels. Alignment of the holes on

I'm going to join the legs with four dowels. Alignment of the holes on

both pieces is critical. The dowel jig

can only make one 1/2" hole at a

time, so I have to align it carefully.

I made a wooden sleeve to fit over the drill bit to act as a depth stop

I made a wooden sleeve to fit over the drill bit to act as a depth stop

...then repositioning and carefully measuring for the next hole

...then repositioning and carefully measuring for the next hole

The legs are wider than the dowel jig opens up, and I also want to

The legs are wider than the dowel jig opens up, and I also want to

drill the holes to one side. So I disassembled the dowel jig to

only have one flange on it. I clamped a wooden spacer in on the

other side to give it rigidity.

I'm sure some will suggest a DowelMax for this job. It's a very flexible jig,

but only goes up to 3/8" (10 mm) and it's quite expensive.

Four holes drilled. If they look perfectly aligned by eye

Four holes drilled. If they look perfectly aligned by eye

then they are close enough for a joint.

A tricky part: The mating leg needs to be a mirror image.

A tricky part: The mating leg needs to be a mirror image.

With the 1/2" hole off to one side of the jig, clamping it

With the 1/2" hole off to one side of the jig, clamping it

for the other holes is not ideal. I also had to measure these off a

different edge, seeing that the jig is on the other way around.

Gluing it up. All surfaces get glue applied. I'm using a thin piece

Gluing it up. All surfaces get glue applied. I'm using a thin piece

of wood to apply glue inside the holes.

The joint fully closed with just hand force. though I applied a clamp

The joint fully closed with just hand force. though I applied a clamp

just for good measure.

I need to join two apron-rails with the frames I just built.

I need to join two apron-rails with the frames I just built.

I need to cut a rabbet in the ends of the apron rails for that.

...then breaking the remaining wood with a hammer

...then breaking the remaining wood with a hammer

Finally moving the spinning saw side to side to clean up the bottom,

Finally moving the spinning saw side to side to clean up the bottom,

similar to this technique.

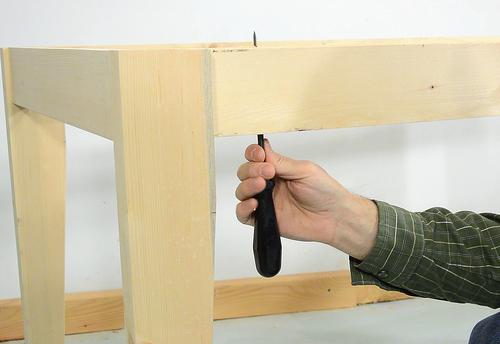

Some screws, at an angle, will hold the apron rail in place

Some screws, at an angle, will hold the apron rail in place

Drilling the screw holes. Easier done from the back.

Drilling the screw holes. Easier done from the back.

Adding countersinks for the screw heads.

Adding countersinks for the screw heads.

Three long and two short screws will hold the rail securely

in place.

Three long and two short screws will hold the rail securely

in place.

Pocket holes might be ideal for attaching the table top, but I don't

Pocket holes might be ideal for attaching the table top, but I don't

have a pocket hole jig. So I'm drilling some 1/2" holes through the

rails from the bottom...

... then using a thin 3/16" drill to drill all the way through.

... then using a thin 3/16" drill to drill all the way through.

The drill is just barely long enough. An alternative to drilling

through the apron rails would be to

glue blocks to the side

With the screw recessed deeply in the rail, the tip sticks out just far

With the screw recessed deeply in the rail, the tip sticks out just far

enough to screw into the top.

Screwing on the top. My drill driver bits are too short to reach the

Screwing on the top. My drill driver bits are too short to reach the

screw, so I'm using a plain old screwdriver.

Taking a flying leap onto the table, just to prove it's strong.

Taking a flying leap onto the table, just to prove it's strong.

I'm actually planning on using this table as a workbench.

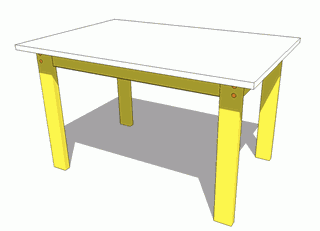

All done. This table is a bit on the tall side, because I intend

to use it as a work surface

All done. This table is a bit on the tall side, because I intend

to use it as a work surface

More about building

More about building Large knock-down table (easy to take apart for moving)

Large knock-down table (easy to take apart for moving) Building a round

Building a round Simple bed from

Simple bed from Simple workbench

Simple workbench Free simple table plans

Free simple table plans Quickie workbench

Quickie workbench