Wooden xylophone toy build

Our two year old likes banging on drums, so we thought about getting him a drum

for Christmas. But then I had the idea of making something with a more pleasing

sound and not as loud: A sort of wooden xylophone.

Our two year old likes banging on drums, so we thought about getting him a drum

for Christmas. But then I had the idea of making something with a more pleasing

sound and not as loud: A sort of wooden xylophone.

Some leftover floor boards had a nice sound when struck, so I figure those would be good. I experimented with different ways of supporting them. Rubber bands worked ok. Having a cavity underneath the board considerably enhanced the sound.

I was even able to use a piano tuner app to get a pitch reading off of them, so

I got all carried away trying to make tuned plates.

I was even able to use a piano tuner app to get a pitch reading off of them, so

I got all carried away trying to make tuned plates.

But different boards would produce different pitches independent of size,

probably due to wood density. They are also very sensitive to how deep

the cut-out is in the back. The cut-out lowers the resonant pitch considerably.

But different boards would produce different pitches independent of size,

probably due to wood density. They are also very sensitive to how deep

the cut-out is in the back. The cut-out lowers the resonant pitch considerably.

After a lot of fussing around trying to tune them and over and under correcting,

I decided just a bunch of pitches that sound nice together would be enough. Laying

them on a bed made them sound enough that I could hear how they sounded together.

After a lot of fussing around trying to tune them and over and under correcting,

I decided just a bunch of pitches that sound nice together would be enough. Laying

them on a bed made them sound enough that I could hear how they sounded together.

Next I needed some sort of box for these to mount to. I worked out where the nodes

of vibration for the plates is based on finding spots where striking them produced

the least amount of tone and marked those locations.

Next I needed some sort of box for these to mount to. I worked out where the nodes

of vibration for the plates is based on finding spots where striking them produced

the least amount of tone and marked those locations.

I put sticks over those marks to figure out the geometry of the box that they should go on to. From that I derived the angle for the joints.

I then made a wedge of that angle to place in my box joint jig.

First I cut the joints in the ends of the long pieces. I put the piece

in the jig so it was angled the same way each time.

I then made a wedge of that angle to place in my box joint jig.

First I cut the joints in the ends of the long pieces. I put the piece

in the jig so it was angled the same way each time.

I used 1/4" box joints, but the workpiece was a bit over an odd number of quarter

inches wide, so there is a wide finger at the top left and the bottom right.

Asymmetrical. To avoid this, I would have had to put the workpiece in the jig

the other way around for half the ends, or initially center the joints, or make the box

an odd number of quarter inches wide.

I used 1/4" box joints, but the workpiece was a bit over an odd number of quarter

inches wide, so there is a wide finger at the top left and the bottom right.

Asymmetrical. To avoid this, I would have had to put the workpiece in the jig

the other way around for half the ends, or initially center the joints, or make the box

an odd number of quarter inches wide.

Whatever I could have done to avoid this asymmetry, it was too late now, so I figured I'd just make the mating pieces asymmetrical the same way.

And matching the asymmetry was easy enough, all I had to do was put the piece in

the same way for each end, just like I had done with the other pieces.

And matching the asymmetry was easy enough, all I had to do was put the piece in

the same way for each end, just like I had done with the other pieces.

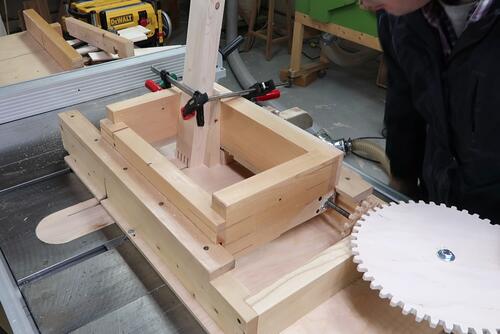

Clamping the short last piece in was kind of tricky, and I used a carriage bolt

braced against the back of the box with a wing nut to clamp it in place.

I last used a screw like that when I made

small boxes so I already had the a hole in the right spot

in the box joint jig for that.

Clamping the short last piece in was kind of tricky, and I used a carriage bolt

braced against the back of the box with a wing nut to clamp it in place.

I last used a screw like that when I made

small boxes so I already had the a hole in the right spot

in the box joint jig for that.

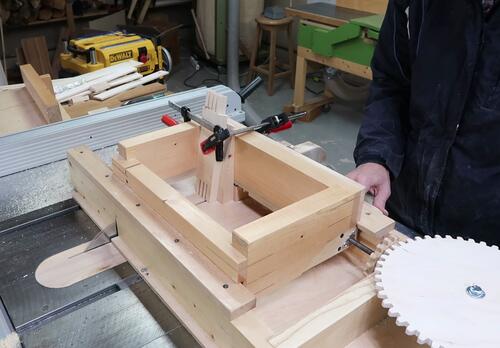

Test fitting it together, the joints were quite snug.

Test fitting it together, the joints were quite snug.

But I figured maybe I made the box a bit too heavy, so I cut away part

of the inside bottom of the wider side pieces on the bandsaw. I made

the side pieces wide to give me extra latitude for how to mount the plates.

But I figured maybe I made the box a bit too heavy, so I cut away part

of the inside bottom of the wider side pieces on the bandsaw. I made

the side pieces wide to give me extra latitude for how to mount the plates.

Then gluing it together. It was hard to force the pieces together once the

glue had swelled them slightly.

Then gluing it together. It was hard to force the pieces together once the

glue had swelled them slightly.

I had to run and get a clamp to squeeze the joint closed.

I had to run and get a clamp to squeeze the joint closed.

Then trimming it to get everything perfectly flush, and rounding the

corners on the belt sander.

Then trimming it to get everything perfectly flush, and rounding the

corners on the belt sander.

With the plates placed directly on the box, they already made recognizable

xylophone like sounds. I experimented with different softer materials

to rest them on to let them vibrate better, including rubber bands,

thin felt, and thick wool felt from a wool cushion that we accidentally

ran through the washer with hot water.

With the plates placed directly on the box, they already made recognizable

xylophone like sounds. I experimented with different softer materials

to rest them on to let them vibrate better, including rubber bands,

thin felt, and thick wool felt from a wool cushion that we accidentally

ran through the washer with hot water.

The thick wool felt sounded the best.

Before drilling mounting holes through the plates, I fine-tuned where the

nodes of vibrations are with the plates upside down on the base, resting on

the wool felt. I marked the "deadest" spot.

Before drilling mounting holes through the plates, I fine-tuned where the

nodes of vibrations are with the plates upside down on the base, resting on

the wool felt. I marked the "deadest" spot.

Then drilled holes, and added large countersinks so that the mounting screws

could be flush with the surface and still have lots of play.

Then drilled holes, and added large countersinks so that the mounting screws

could be flush with the surface and still have lots of play.

On a real marimba, the plates are mounted with strings going through the sides, but for a kids toy, that wouldn't be robust enough.

I was hoping that with the screws at the nodes of vibration, I could just

screw them down loosely, but with the screw touching the plates and still

get a decent sound. But the screw on the plates really dampened the sound.

I was hoping that with the screws at the nodes of vibration, I could just

screw them down loosely, but with the screw touching the plates and still

get a decent sound. But the screw on the plates really dampened the sound.

But regardless of how or whether I'd solve that problem, I knew I'd mount

the plates with screws.

But regardless of how or whether I'd solve that problem, I knew I'd mount

the plates with screws.

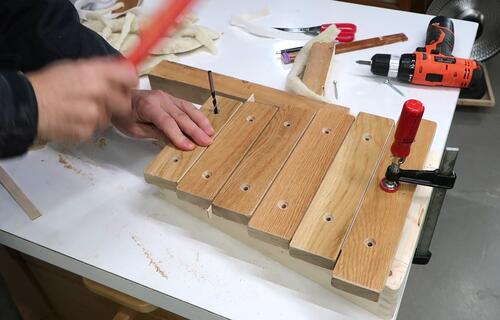

I made some 1 mm thick spacers to go between the plates, arranged them on the box, clamped the largest one in place, then put a brad point drill bit in each hole and whacked it with a push stick to mark the mounting hole locations.

Then drilling pilot holes for the screws. Pilot holes weren't strictly necessary

but I didn't want to risk splitting the wood. They also help to locate the

screws more precisely later.

Then drilling pilot holes for the screws. Pilot holes weren't strictly necessary

but I didn't want to risk splitting the wood. They also help to locate the

screws more precisely later.

Attaching small wool felt pads next to the holes with hot glue.

Attaching small wool felt pads next to the holes with hot glue.

Then attaching the plates with screws and felt washers. I enlarged the shank

hole so that only the felt washer under the screw head would contact the

wood.

Then attaching the plates with screws and felt washers. I enlarged the shank

hole so that only the felt washer under the screw head would contact the

wood.

But I the felt stuck out just a little bit, and I figured the kids would probably end up pulling at it.

To solve that, I drilled holes in the top to sink the screw head and felt washer

a few millimeters below the surface.

To solve that, I drilled holes in the top to sink the screw head and felt washer

a few millimeters below the surface.

I used some punches (which were meant for leather work) to make the felt washers.

First a small punch for the center hole, then a large punch to cut the perimeter.

I used some punches (which were meant for leather work) to make the felt washers.

First a small punch for the center hole, then a large punch to cut the perimeter.

The sound was quite good with this solution. The screws and felt washers didn't

dampen the vibrations.

The sound was quite good with this solution. The screws and felt washers didn't

dampen the vibrations.

I still needed a mallet for the xylophone. Ideally, it would have rubber around

it, but that would get pulled off by the kids for sure. So I used some very

light and relatively soft wood to make the mallet head.

I still needed a mallet for the xylophone. Ideally, it would have rubber around

it, but that would get pulled off by the kids for sure. So I used some very

light and relatively soft wood to make the mallet head.

After gluing it to the stick, I spun it against the belt sanders to turn it into a nice ball shape.

All of the striking surface of the mallet head is side grain, so it's less hard than

the plates.

All of the striking surface of the mallet head is side grain, so it's less hard than

the plates.

I liked the sound of this. It's more of a hard pinging sound, not as soft and pure as

with the rubber band on the end of a stick.

But it's very distinct. And, being softer than

the plates, doesn't dent them either.

I liked the sound of this. It's more of a hard pinging sound, not as soft and pure as

with the rubber band on the end of a stick.

But it's very distinct. And, being softer than

the plates, doesn't dent them either.

A few weeks later at Christmas. The xylophone toy got lots of bashin on, so far

standing up well to it.

A few weeks later at Christmas. The xylophone toy got lots of bashin on, so far

standing up well to it.

See also:

Ukulele build

Ukulele build Building a cajon box drum, with Paul

Building a cajon box drum, with Paul Marble machine 2.1

Marble machine 2.1 Making a loony whistle

Making a loony whistle Homemade pipe organ

Homemade pipe organ A bell that rings two notes at once

A bell that rings two notes at once Anti ASMR screeching and scraping sounds

Anti ASMR screeching and scraping sounds More wooden toy projects

More wooden toy projects